It is frustrating when the first snow falls and your snowblower won’t start. Don’t be stuck in the garage on Thanksgiving tearing apart your snowblower carburetor. Here’s how to make sure your snowblower fires right up.

Fuel delivery

A snowblower that won’t start is typically due to a fuel delivery problem. The months your snowblower spends in the garage doing nothing causes the gasoline to break down, forming varnish and gum that can clog the tiny passages or stick the float in the carburetor.

Varnish prevents gasoline from reaching the combustion chamber, meaning the snowblower won’t start no matter how many times you pull the starter cord or how much starter fluid you empty into the intake.

Remove the float bowl and spray carburetor cleaner into the carb. This simple procedure will often clean whatever is fouling the carburetor and restore fuel-flow.

If that doesn’t work, remove the carburetor and disassemble it to give it a thorough cleaning. Take pictures on your phone to aid in reassembly. Note the number of revolutions it takes to remove any needle valves to ensure you reinstall them correctly.

Pro tip: Taking apart a carburetor is far easier than reassembling one. If you’re apprehensive, find a good mechanic.

Preventing fuel problems

It doesn’t take much to plug the tiny orifices in a carburetor, and while cleaning a carburetor isn’t too difficult, not cleaning one is even better. Here’s how to maintain your snowblower so you won’t have to clean the carb every year.

One option is to shut off the fuel line and run the engine until the carburetor empties and the engine stops. This helps prevent stale fuel from creating varnish and gum and plugging fuel passages while your snowblower is in storage.

However, leaving the carburetor empty and exposed to air hastens oxidation. Fluctuating temperatures and humidity while in storage can also lead to condensation and moisture accumulation.

Another option is to add AMSOIL Gasoline Stabilizer to the tank and run the engine for a few minutes to distribute the treated gas throughout the system before putting the snowblower into storage. The treated fuel in the carburetor bowl provides protection from oxidation and moisture and helps keep gum and varnish from forming on components.

Ethanol

When water infiltrates your gas tank in the form of melted snow or condensation, it can cause phase separation, a phenomenon that occurs when the bond between ethanol (present in most gasoline) and gasoline breaks. When this ethanol/water mixture enters the combustion chamber, it creates a lean-burn situation that can damage your engine.

For best performance, use premium 91-octane, non-oxygenated (ethanol-free) gas. Many gas stations offer non-oxygenated gas and advertise it for powersports and off-road use, which includes your landscaping equipment and snowblower.

It’s more expensive but spending a few extra dollars a year to help your equipment run stronger and last longer should be an easy decision. At the very least, fill the tank with ethanol-free gas before storage to help ward off phase separation.

When using ethanol-blended gas add AMSOIL Quickshot to address ethanol-related performance issues including phase separation.

Change the oil

Used oil contains acids that slowly corrode metal components. Prior to storage, change the oil to remove acidic byproducts and ensure maximum protection throughout the summer. After changing the oil, run the engine for a couple of minutes to distribute oil throughout the entire engine.

Fogging

Use AMSOIL Engine Fogging Oil to protect the upper end (cylinder, piston, valves) from corrosion during storage. Remove the spark plug, which is the perfect time to inspect its condition, and spray a little oil into the cylinder. Gently pull the starter cord a few times to distribute the oil, then replace the plug.

Gear housing

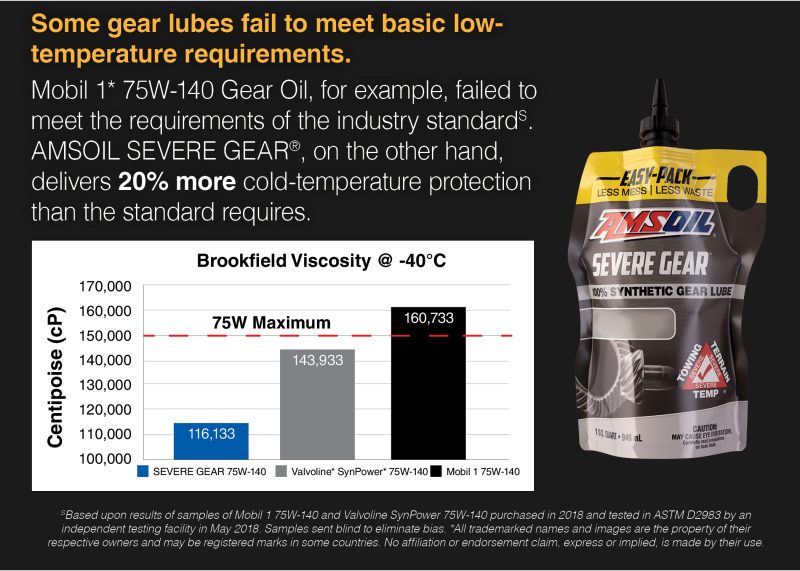

Clean any debris from around the filler port on the auger gear housing, remove the plug and ensure the gear oil level is up to the top. If not, add the correct lubricant (check your owner’s manual for viscosity).

Belts and linkages

Stressing a worn belt after it’s been sitting idle for months is a recipe for a breakdown. Belts frequently break while clearing the first big snowfall of the year. Spring is the prime time to check the condition and replace worn drive belts and linkages. It’s easier and more comfortable to do any maintenance on your snowblower on a mild, spring day than in winter.

Pro tip: Start your snowblower a few weeks before the first expected snow to ensure it’s ready to go!

Performing these simple maintenance tasks in the warmer months lowers the probability of your snowblower not starting and provides plenty of time to fix any problems before the first snow.

Comments

AMSOIL Technical Writer and 20-year veteran of the motorcycle industry. Enjoys tearing things apart to figure out how they work. If it can’t be repaired, it’s not worth owning.

Share: