In classic car and hot rod engines, use a high-zinc motor oil all the time. Read on for details.

- What is high-zinc motor oil?

- How do ZDDP additives work?

- Flat-tappet cams vs. roller cams

- The role of piston rings

- Do you always need an oil with ZDDP additives?

Thanks to Hugh Ashburn for asking on our Facebook page about using high-zinc oil in older engines. Specifically, should you use a motor oil with ZDDP additives only during engine break-in or throughout the engine’s lifespan?

What is high-zinc motor oil?

Zinc dialkyldithiophosphate (ZDDP) is the most common zinc-based additive and is used primarily as an anti-wear agent to prevent premature engine wear. It also provides corrosion and oxidation protection.

However, because the zinc and phosphorus found in ZDDP can negatively affect catalytic converters, it has been phased out of motor oil formulations in recent years.

Reducing ZDDP has drawbacks, as classic-car owners have found. Older vehicles with flat-tappet camshafts and, in particular, engines that include high-tension valve springs or other modifications that create high contact pressures, can suffer premature wear due to reduced ZDDP levels.

For best protection, engine builders and gearheads typically use high-zinc and high-phosphorus motor oil to offer extra protection for flat-tappet cams, lifters and other components during break-in.

AMSOIL Break-In Oil, for example, contains 2,200 ppm zinc and 2,000 ppm phosphorus.

How do ZDDP additives work?

ZDDP anti-wear additives are heat-activated, meaning they provide wear protection in areas of increased friction.

As temperatures rise and surfaces come closer together, ZDDP decomposes and the resulting chemistry protects critical metal surfaces.

When parts move during operation, any sliding or rolling motion takes place on top of or within the ZDDP anti-wear film, which reduces metal-to-metal contact.

This is especially important in engines with flat-tappet camshafts or engines modified to create more horsepower. High-tension valve springs, often used in racing applications, also increase the potential for cam wear and require additional ZDDP.

Flat-tappet cams vs. roller cams

The design of flat-tappet cams makes them especially vulnerable to wear. As the name indicates, the tappet – or lifter – is flat. During operation, the cam-lobe slides rapidly over the tappet, increasing friction and temperatures.

A thin oil film is the only barrier that prevents the lifter and cam lobe from welding together.

If the oil film fails or provides insufficient wear protection, the two components can eventually wear the flat-tappet cam and affect valve operation.

Engine power and efficiency can decline if the flat-tappet cam cannot lift the valves enough to adequately charge the chamber for ignition or release exhaust fumes. Because most V-8 engines of the muscle-car era came standard with flat-tappet cams, the problem is especially prevalent to classic-car and hot rod owners.

Roller cams, on the other hand, are differentiated by rolling contact rather than sliding contact. Although costlier, roller cams are common in most modern vehicles and can be retrofitted into classic-car and hot-rod engines.

The role of piston rings

Even though Hugh didn’t ask about it specifically, I should also mention the importance of seating the piston rings during break-in.

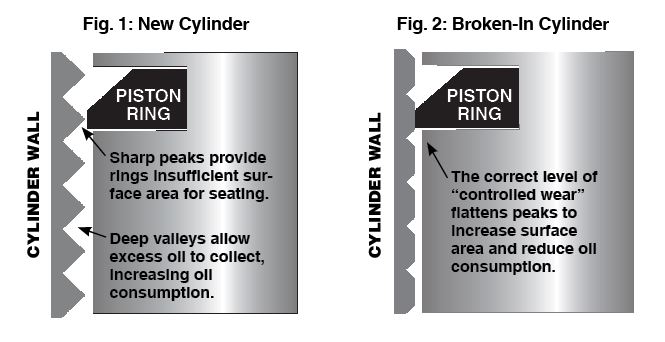

Although a new or freshly honed cylinder appears smooth to the naked eye, it actually contains microscopic peaks and valleys. If the valleys are too deep, they collect excess oil, which burns during combustion and leads to oil consumption.

The sharp peaks, meanwhile, provide insufficient area to allow the rings to seat tightly. That means highly pressurized combustion gases can blow past the rings and into the crankcase, reducing horsepower and contaminating the oil.

Find out why championship engine builder Jesse Prather requires his customers to use AMSOIL Break-In Oil.

Breaking in the engine wears the cylinder-wall asperities, providing increased surface area for the rings to seat tightly. The result is maximum compression (i.e. power) and minimum oil consumption.

Do you always need an oil with ZDDP additives?

Do you need to use high-zinc motor oil in an older engine after break-in, which is typically about 500 miles?

Yes, if you want to maintain horsepower and promote longevity.

Even after the cam has seasoned, it’s still exposed to tremendous heat and pressure, especially in a heavily modified or racing engine. The constant barrage of pressure can rupture the oil film responsible for preventing wear, leading to metal-to-metal contact.

After break-in, we recommend using an oil with at least 1,000 ppm ZDDP in a flat-tappet engine.

That way, you’re providing your expensive engine with maximum protection against wear and horsepower loss.

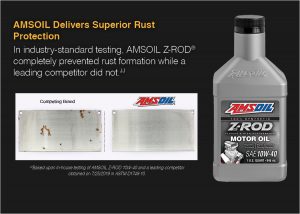

AMSOIL Z-ROD Synthetic Motor Oil, our primary recommendation for classic cars and hot rods, contains more than…

- 1,400 ppm zinc

- 1,300 ppm phosphorus

Z-ROD also contains potent corrosion inhibitors that protect your engine from rust and corrosion during storage.

Updated. Originally published Aug. 25, 2017.

Comments

AMSOIL Technical Writer and avid avid DIYer with 12 years in the synthetic lubricants industry, who enjoys making technical topics in the automotive, powersports and industrial markets easy to understand.

Share: