Hydraulics are essential to the operation of commercial equipment, using pressurized fluid to complete jobs that would otherwise be impossible or highly inefficient.

Hydraulic systems operate based on Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle allows hydraulic systems to amplify force that allows heavy lifting with precise control.

COMMERCIAL APPLICATIONS

• Excavators and loaders use hydraulic systems for digging, lifting and handling materials.

• Cranes use hydraulic systems to lift and position heavy loads.

• Telehandlers use hydraulic systems for precise placement of materials.

• Tractors use hydraulic systems for lifting implements like plows and seeders.

• Harvesters use hydraulic systems for cutting, threshing and handling grain.

• Sprayers and spreaders use hydraulic systems for even distribution of fertilizers and pesticides.

HYDRAULIC-SYSTEM COMPONENTS

Each component in the hydraulic system plays a specific and important role. Routine inspection and maintenance are critical for keeping systems in peak condition.

Hydraulic Pump

The hydraulic pump converts mechanical energy from an engine into hydraulic energy by pressurizing and circulating fluid throughout the system to power various actuators such as cylinders and motors. Common hydraulic-pump problems include cavitation, wear of internal surfaces and seal failure.

Key Maintenance

• Keep hydraulic fluid clean and free from contaminants.

• Regularly inspect the inlet line for blockages or leaks.

• Perform routine pressure tests to ensure the pump is working at optimal capacity.

Control Valves

Control valves direct the flow of pressurized fluid to specific actuators, regulating the movement, speed and force of the machinery. Common control-valve problems include valve sticking, internal leaks caused by wear in the valve body or seals and damaged linkage or solenoids (in electrically actuated valves).

Key Maintenance

• Clean valves periodically to avoid blockages or debris buildup.

• Inspect for worn-out seals and replace as needed.

• Verify proper calibration and adjust as necessary.

Hydraulic Cylinders

Hydraulic cylinders convert hydraulic energy into mechanical force for lifting, pushing and pulling. Hydraulic fluid enters the cylinder through an inlet port, pushing the piston inside. The movement of the piston extends or retracts the cylinder rod, creating mechanical motion. Common cylinder problems include seal deterioration, rod scoring or pitting, bent rods from overloading or misalignment and fluid leaks around the piston.

Key Maintenance

• Replace seals regularly to avoid leaks.

• Inspect rods for wear, corrosion or bending and repair or replace as needed.

• Ensure cylinders are correctly aligned to prevent undue stress on components.

Reservoir

The reservoir provides a ready supply of hydraulic fluid to the pump, collects fluid returning from the system and helps dissipate heat. Proper fluid levels ensure consistent operation and prevent air from entering the system. Common reservoir problems include contamination, overheating, corrosion and cracking.

Key Maintenance

• Routinely check fluid levels and top off when necessary.

• Use clean, sealed containers when adding fluid to prevent contamination.

• Flush the reservoir periodically to remove debris and sediment.

Hoses and Fittings

Flexible hoses and rigid pipes transport hydraulic fluid, while fittings connect hoses to other components to ensure secure, leak-free connections. Common hose and fitting problems include abrasion or cracking, burst hoses and loose or leaking fittings.

Key Maintenance

• Routinely inspect hoses for cracks, kinks or abrasion marks.

• Secure hoses properly with clamps to prevent rubbing or pinching.

• Replace fittings that show corrosion, wear or inadequate sealing.

Filters

Filters are located at key points in the hydraulic system, including the reservoir outlet and return lines, to trap contaminants before they enter the pump or other components. Common filter problems include clogging and bypass-valve activation that allows unfiltered fluid to enter the system.

Key Maintenance

• Replace filters at the recommended intervals, or sooner in extreme environments.

• Use filters compatible with the specific hydraulic fluid.

• Monitor filter pressure indicators to identify blockages early.

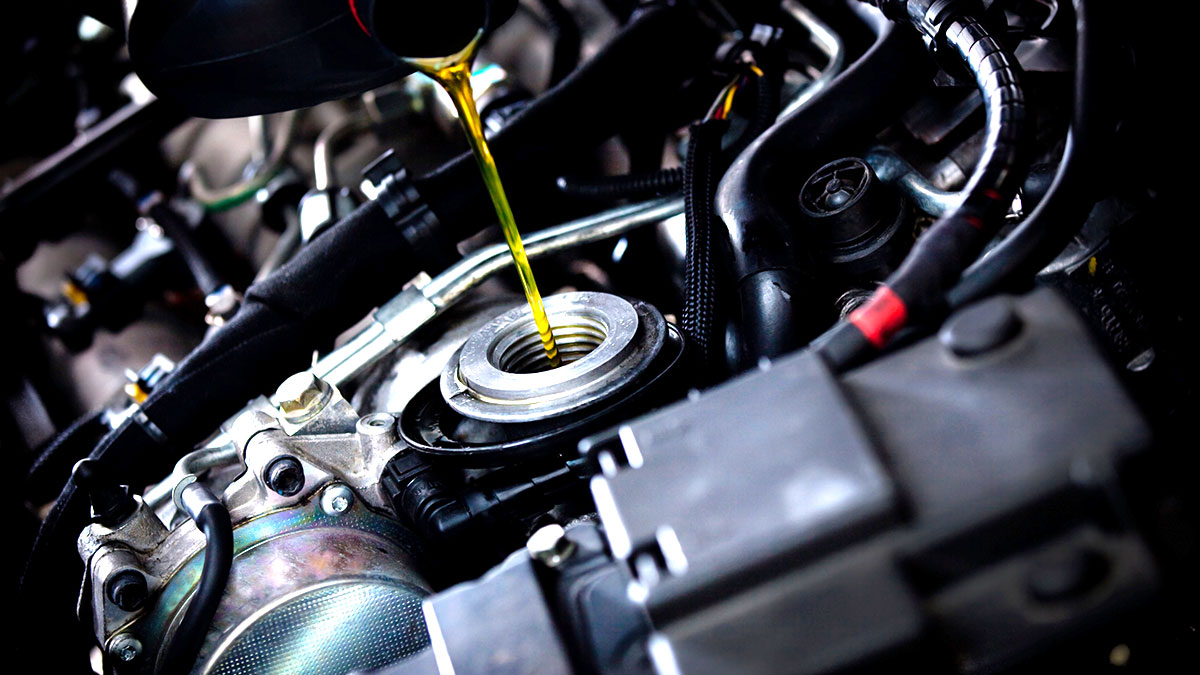

THE ROLE OF HYDRAULIC FLUID

Hydraulic fluid is the primary medium through which energy is transferred in a hydraulic system. It is responsible for the following tasks:

Power Transmission

The hydraulic fluid transmits energy from the pump to the actuators, including hydraulic cylinders and motors. High-pressure fluid generates the force necessary to perform operations.

Component Protection

The hydraulic fluid reduces friction and cushions moving parts, preventing premature wear and overheating. For example, the pistons in a hydraulic cylinder rely on the hydraulic fluid to create a smooth, continuous motion.

Heat Dissipation

The hydraulic fluid helps absorb and transfer heat away from critical components.

Sealing Properties

Hydraulic fluid helps form a seal within cylinders to maintain pressure and prevent internal leaks.

Contaminant Removal

Hydraulic fluid helps carry contaminants to the reservoir, where filters remove them from the system.

Hydraulic-Fluid Maintenance

Hydraulic fluid absorbs dirt, water and other impurities during operation, reducing protection and performance. Staying on top of fluid maintenance ensures consistent protection and performance, while reducing the risk of costly repairs and downtime.

AMSOIL HYDRAULIC OILS

AMSOIL hydraulic oils provide significant benefits and cost savings.

AMSOIL Synthetic Anti-Wear Hydraulic Oil

ISO 22 (AWG), ISO 32 (AWH), ISO 46 (AWI)

Offers superior protection for hard-working hydraulic systems from the stress of high-pressure, high-load and heavy-duty operations.

AMSOIL Synthetic Multi-Viscosity Hydraulic Oil

ISO 22 (HVG), ISO 32 (HVH), ISO 46 (HVI), ISO 68 (HVJ)

Cost-effective formulation that provides all-season protection and reliable operation in most types of hydraulic systems.

AMSOIL Commercial-Grade Hydraulic Oil

ISO 32 (HCG32), ISO 46 (HCG46), ISO 68 (HCG68)

Formulated to protect industrial and mobile hydraulic applications. Resists oxidation, fights corrosion and inhibits foam to help maintain component cleanliness and promote efficient operation.

AMSOIL Synthetic Biodegradable Hydraulic Oil

ISO 46 (BHO)

Synthetic formulation delivers the ideal combination of excellent biodegradability and wear protection for mobile and stationary hydraulic applications.

Comments

AMSOIL Lead Technical Writer for more than two decades.

Share: