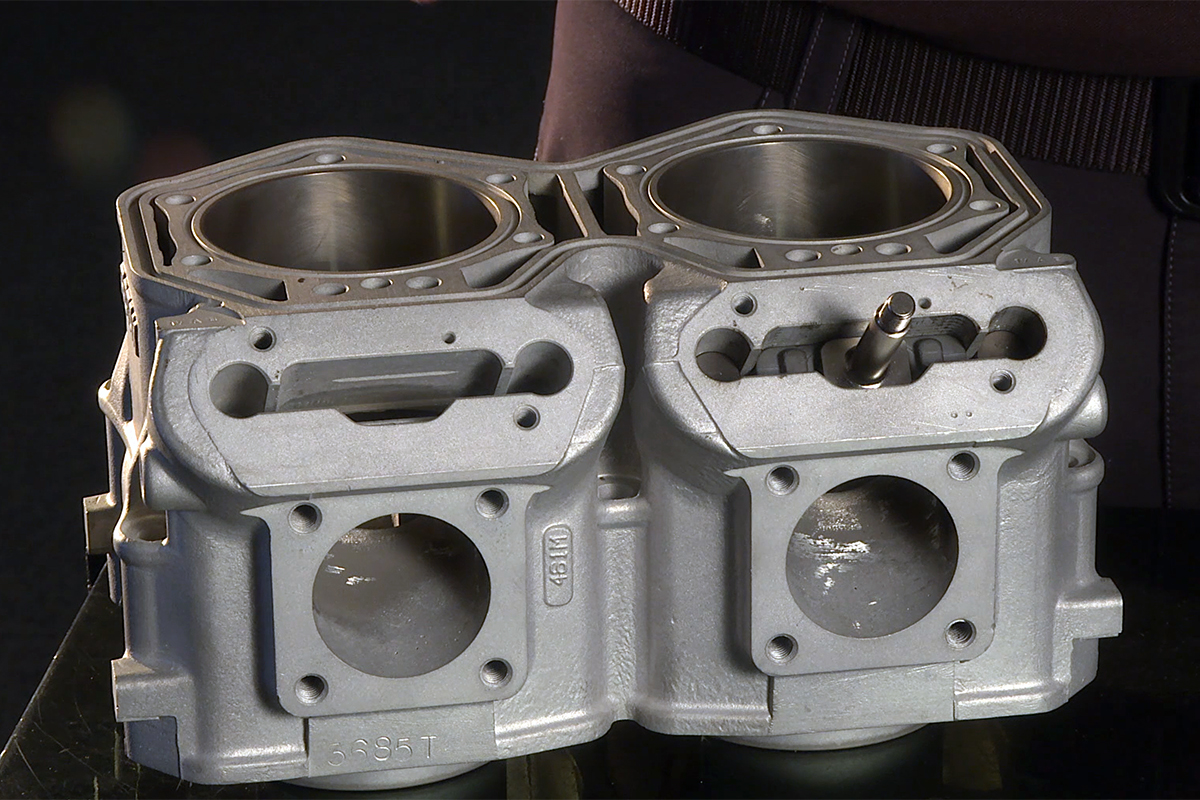

All engines draw air into the cylinder for combustion and expel the spent gases through an exhaust system. Exhaust power valves improve two-stroke engine performance by managing exhaust-port timing to maintain optimal throttle response and power delivery at any engine speed.

Why exhaust power valves matter.

Small exhaust ports increase air velocity, which translates into improved power and throttle response at low rpm. However, small ports cannot move enough air as engine speeds increase, leading to reduced high-rpm performance. In other words, a narrow exhaust port will be more powerful launching the machine from a stop but lack top-end power. Large exhaust ports create the opposite effect, reducing low-rpm air velocity, throttle response and power, but increasing top-end power.

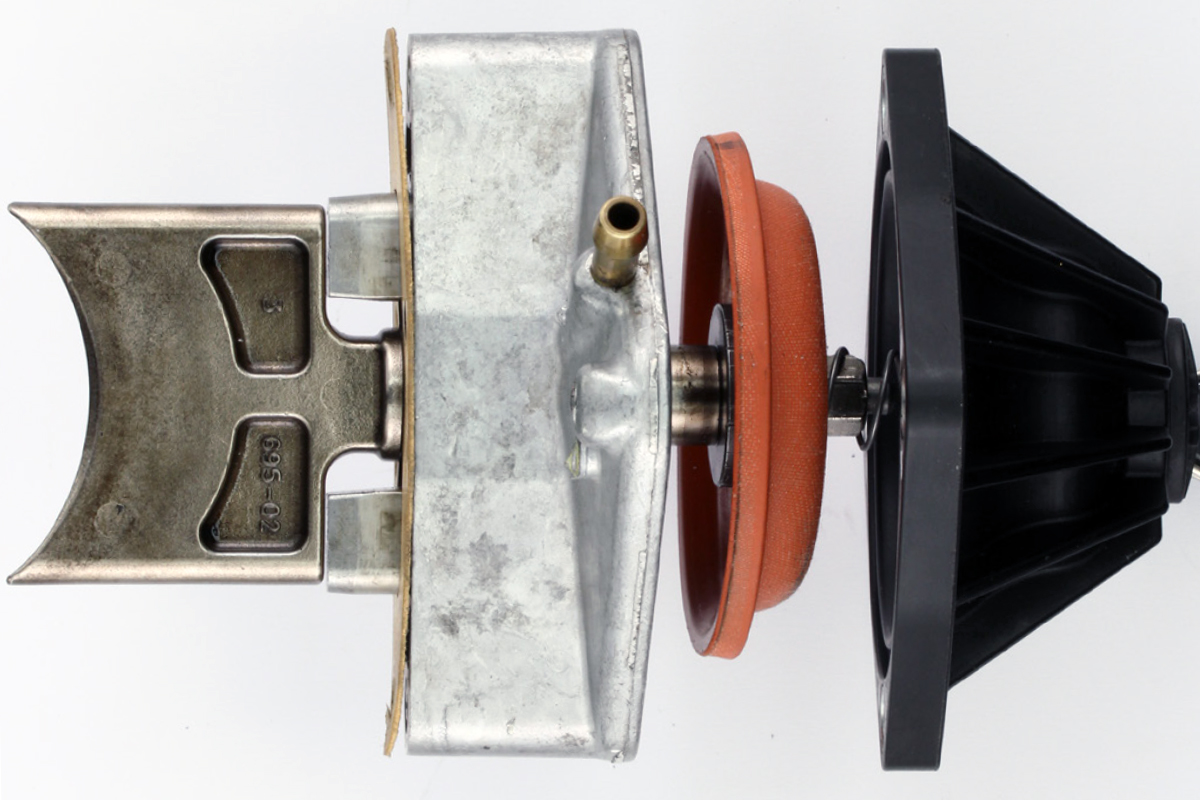

To solve this problem, engineers designed variable valves for two-stroke exhaust ports that change size relative to operating conditions. Adjustable exhaust power valves were introduced more than 50 years ago. Early examples included the Yamaha Power Valve System (YPVS) and Rotax Adjustable Variable Exhaust (RAVE). Some riders generically refer to all exhaust power valves as RAVE valves.

How exhaust power valves work.

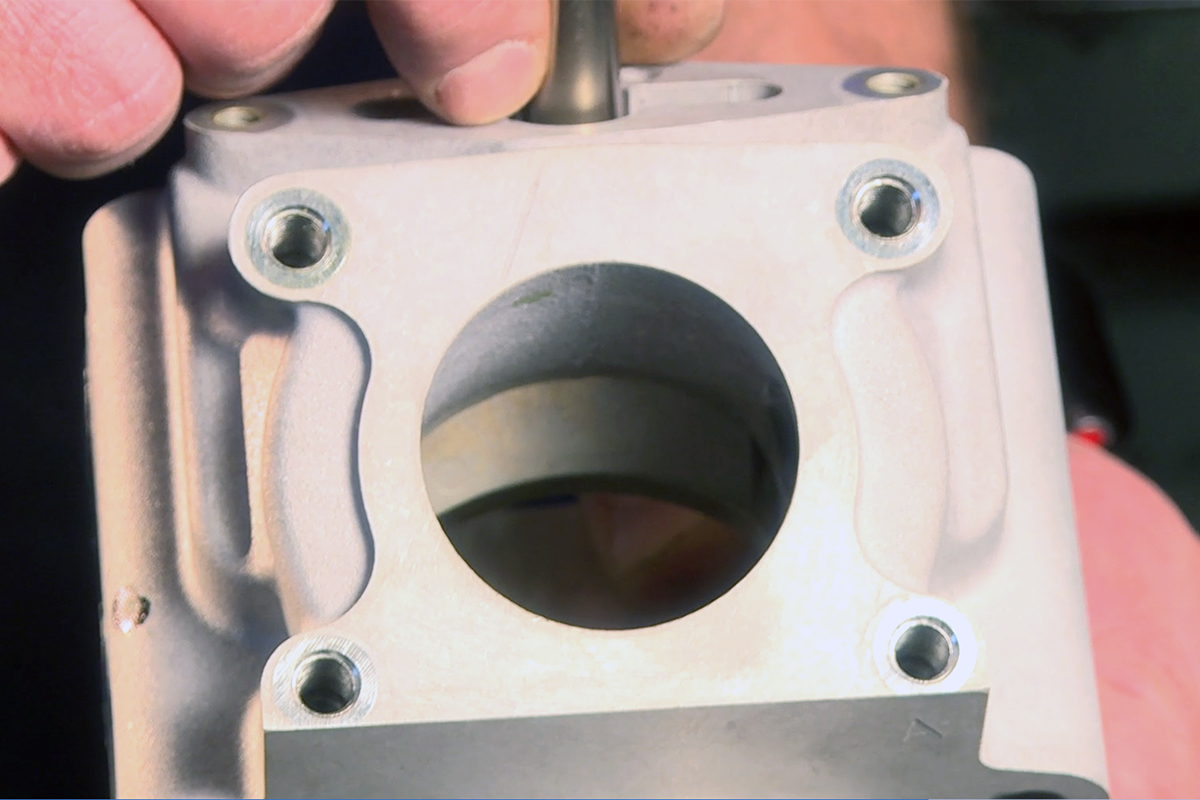

Two-stroke exhaust power valves are designed to dynamically adjust the exhaust port size in response to varying engine speeds. At low engine speeds, the power valve covers a portion of the exhaust port, creating better low-rpm performance. The valve retracts as engine speed increases, creating a larger exhaust port to maximize high-speed power.

Older mechanical exhaust power valves relied on air and spring pressures to open and close depending on operating conditions. Though not as tunable as modern technology, they were extremely reliable. Modern exhaust power valves monitor engine-speed and throttle-position data electronically and continuously adjust the port size for optimal performance.

Exhaust power valve challenges.

Minimal force is used to activate power valves, so even moderate restriction can render the valve inoperable and periodic maintenance becomes necessary to maintain peak performance. Because the power valves are located within the exhaust stream they are exposed to high temperatures and a constant flow of contaminates. The combination of carbonaceous material, unburned fuel and oil residue can form deposits on power valves, restricting their movement.

Two-stroke engines burn oil during combustion and the exhaust gases can reach 1,000ºF (538ºC), making them extremely sensitive to oil quality. Low-quality oil doesn’t burn cleanly, causing excessive deposits to accumulate on the power valves. Eventually, these deposits get thick enough to cause the valve to stop moving, greatly reducing engine power and performance. Snowmobile manufacturers recommend that valve cleaning be performed at least annually and at most every 1,000 miles. Engines subjected to extensive idle or operation at continuous low speeds may require more frequent valve service.

Additionally, modern two-stroke engines are primarily found in off-road and racing vehicles, including snowmobiles, dirt bikes and go karts, so the importance of power valve maintenance has become an afterthought for many.

Spend more time riding.

Discoloration and deposits are normal, but exhaust power valves should move freely with little or no resistance. Hard, dry carbon is worse than soft, oily deposits. Use AMSOIL Power Foam to dissolve accumulated residue and a non-metallic brush to remove deposits without damaging the valve surfaces.

To reduce maintenance and help maintain peak engine performance, AMSOIL INTERCEPTOR® Synthetic 2-Stroke Oil burns cleaner to inhibit deposit formation, prevent valve sticking, maximize engine performance and extend maintenance intervals.

Comments

AMSOIL Technical Writer and 20-year veteran of the motorcycle industry. Enjoys tearing things apart to figure out how they work. If it can’t be repaired, it’s not worth owning.

Share: