Nothing has scared off would-be mechanics over the years like the automatic transmission. Its array of gears, clutches, solenoids and other components somehow conspire to automatically select the best gear ratio depending on driving conditions. As a result, you get maximum fuel economy and drivability.

-

What goes on inside this modern marvel?

-

How can you idle without the vehicle moving?

-

How does it shift gears?

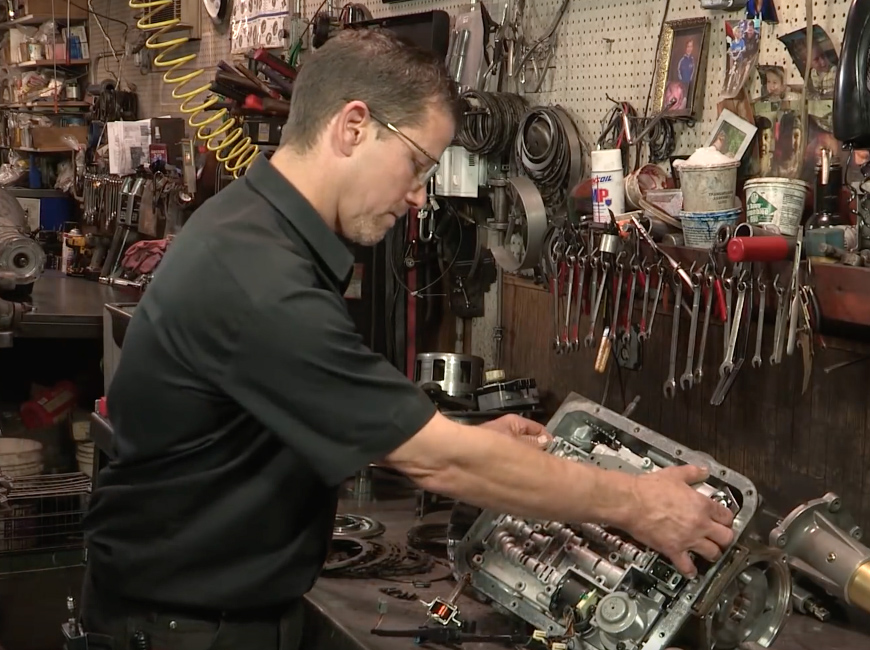

Cutaway of an automatic transmission torque converter.

In most automatic transmissions, a torque converter connects the engine to the transmission. It’s a mechanical device that sort of looks like a giant donut filled with fins, a stator, an impeller and other components.

When you step on the accelerator, the half of the torque converter connected to the engine spins. Transmission fluid inside the torque converter, in turn, rotates and begins to spin the half of the torque converter connected to the transmission. In this way, the fluid inside the torque converter transfers the rotational force of the engine to the transmission.

To illustrate, imagine you have a pair of electric fans. Position them so they’re facing each other. When you turn on one fan, it’ll begin to rotate the other fan. That’s because the air around the fan transfers energy to the stationary fan. That’s how you can couple the two together without using a mechanical connection. And that’s how your engine can idle without the vehicle moving – the idling engine lacks power to spin the torque converter with enough force to turn the transmission input shaft.

Let’s shift gears

So, you’ve jammed the accelerator to the floor. The half of the torque converter connected to the engine now spins with enough force to turn the half connected to the transmission. Away you go.

Engine rpm climbs, and it’s time to shift gears.

The vehicle’s computer tells the transmission when to shift based on vehicle rpm, engine load and other factors. When this happens, solenoid valves inside the transmission activate different clutches to select different gears.

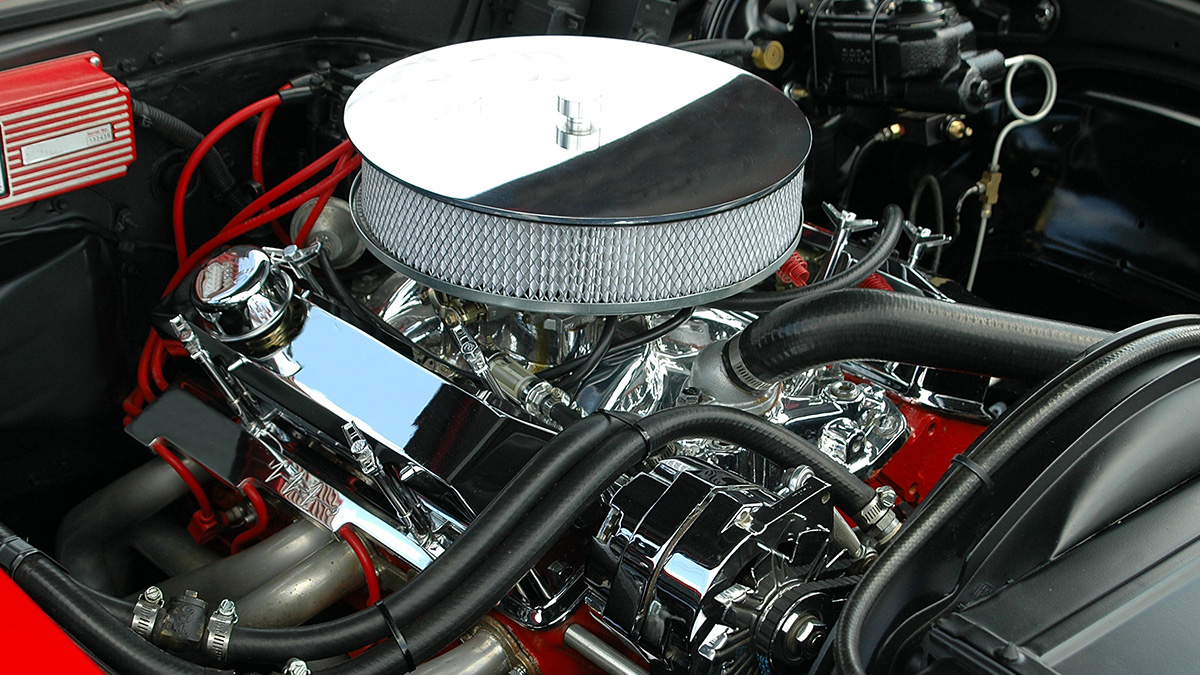

Planetary gear set illustration.

Most automatic transmissions use planetary gear sets. They include a sun gear around which rotate planet gears. A ring gear holds all of them together.

Today’s transmissions, which can provide up to 10 gear ratios, contain several planetary gear sets. Exactly how they work together is complicated. The basic idea, however, is that you can use clutches to allow some components to rotate while holding others stationary, thus changing the overall gear ratio. Transmission fluid that’s pressurized using a pump inside the torque converter activates the clutches that hold the gears stationary. The computer determines which clutches to engage at what time to select the appropriate gear. Depending on the gear the computer selects, the ring gear can be locked while power runs through the sun gear, or vice versa.

Clean, quality fluid

As you can see, the transmission fluid does more than just protect against wear. It also acts as a hydraulic fluid to activate clutches. Plus, it manages friction within the clutches to enable crisp, confident shifts. If the fluid breaks down due to extreme heat, harmful sludge and deposits can form. This can cause the clutch plates to glaze over or the narrow fluid passages inside the transmission to become blocked. Degraded fluid can also lead to stuck valves and reduced frictional properties. Eventually, your transmission shifts hard, slips or hesitates.

Servicing your transmission with high-quality synthetic transmission fluid that resists heat is one of the best – and most cost-effective – ways to ensure it delivers years of reliable service.

Comments

Share: