Motor oil contamination is the result of dirt, fuel, metal particles and other contaminants accumulating in the oil. It also occurs when chemical changes, such as additive depletion and oxidation, take place in the oil itself. For best protection, it’s important to use a good motor oil that resists the effects of contamination and continues to protect your engine well.

Here’s a rundown on the causes of oil contamination.

Abrasives collecting in the oil

Dust and Dirt – The design limitations of air cleaners, some oil-fill caps and crankcase ventilation systems allow a certain level of dust and dirt into the engine. Meanwhile, intake-system leaks can permit unfiltered air to enter the engine.

Properly maintaining the engine and its accessories minimizes the amount of contaminants entering the lubrication system, helping extend engine life.

Metal Particles – Normal engine wear produces tiny metal particles that the oil can collect and circulate through the engine. Particles of road dust and dirt increase wear rates and generate larger, even more abrasive metal particles that can circulate through the engine prior to lodging in the filter.

That’s why it’s vital to use a premium oil filter with a high efficiency rating, like AMSOIL Oil Filters.

Combustion byproducts contaminate oil

Water – Engine combustion produces water vapor, or steam. When engine temperatures are high, most of the water remains in vapor form and exits the exhaust.

However, when engine temperatures are low, such as at startup and during short-trip operation in low ambient temperatures, water vapor condenses (turns into a liquid) on cylinder walls and enters the crankcase, where it leads to sludge and corrosion.

Acids – Combustion produces acidic gases that condense on the cylinder walls in cold temperatures and drip into the crankcase. The gases combine with water to cause rust and corrosion.

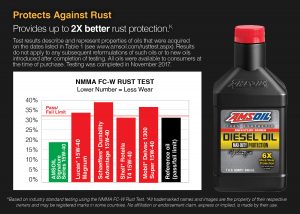

AMSOIL Signature Series Synthetic Diesel Oil delivers excellent protection against rust, as shown here.

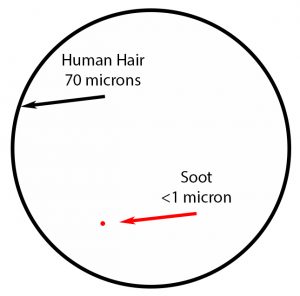

Soot and Carbon – Incomplete combustion produces soot, carbon and other deposit-forming materials. An engine running too “rich,” or with too much fuel, increases contaminant levels. Light-load, low-speed gasoline engine operation and high-load, low-speed diesel engine operation increase levels of these combustion by-products.

Fuel Dilution – Fuel can slip past the piston rings during operation and contaminate the oil in the crankcase. Direct-fuel-injection engines are particularly prone to fuel dilution due to the high pressures under which the fuel is injected into the cylinder.

Fuel dilution reduces oil viscosity, which can decrease oil film strength and increase oil consumption. It also leads to sludge and varnish, which harms your engine and requires you to change oil more often.

Although all motor oils eventually succumb to contamination and must be changed, high-quality synthetic oils – like AMSOIL synthetic motor oils – deliver superior protection for longer due to their high-quality base oils and additives.

Updated. Originally published May 24, 2017.

Comments

Share: