Dry and wet cylinder liners

Dry cylinder liners are commonly used in smaller engines and passenger vehicles where cooling demands are lower. They do not come into direct contact with the engine’s cooling system, but are pressed or fitted into the engine block, which is used for heat dissipation.

Wet cylinder liners are commonly used in heavy-duty engines where efficient cooling is critical. They are in direct contact with and surrounded by the engine’s coolant, helping efficiently dissipate heat. While wet cylinder liners provide better cooling performance, they are more susceptible to corrosion if the cooling system is not properly checked and maintained.

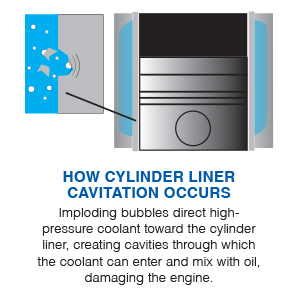

How cylinder-liner cavitation occurs

When the engine is running, the pistons move vertically inside their liners several thousand times per minute. Meanwhile, the rotary motion of the crankshaft applies a thrust force through the connecting rods to the piston. These contradictory movements cause the pistons to hammer the liners, causing significant vibration, similar to the effect of ringing a bell. This vibration can cause air bubbles to form in the coolant surrounding the liner.

When the bubbles rupture, they direct a high-pressure stream of coolant at the liner. Like a rushing river carving away a canyon wall, the coolant can erode the liner until cavities form. Left unchecked, these cavities can keep growing and eventually penetrate the liner, allowing oil and coolant to mix. Once that happens, it’s only a matter of time before the engine fails.

Prevention is the best practice when it comes to cavitation. That task falls on the engine coolant, and there are two ways formulators typically design engine coolant to fight cavitation.

Metallic salts

For years, formulators have added metallic salts, like nitrites and molybdenates, to coolant that attach themselves to the liner and form a sacrificial layer. When the coolant bubbles implode, the metallic salts absorb the pressure and break off from the liner surface rather than the metal itself. Metallic salts naturally deplete over time, meaning motorists must replenish them periodically by adding a supplemental coolant additive (SCA) to the coolant reservoir, typically midway through the service interval. Unfortunately, this is often overlooked.

Organic acid technology

The trend in the coolant market – and the strategy we use at AMSOIL – is to eliminate adding an SCA by formulating coolant with organic acid technology (OAT). The chemistry of OAT coolants passivates the liner surface, which coats it in a thin, inert layer that provides protection against cavitation and corrosion. Unlike metallic salts, the additives in OAT coolants last much longer, eliminating the need to replenish the system with an SCA. Modern OAT coolants also help fight problems associated with traditional “green” coolants, like scaling and additive drop-out (which lead to “slime” in the coolant system) due to incompatibility issues.

Aside from using an OAT coolant, it’s good practice to check coolant levels periodically. Also, make sure to check the pH and glycol levels annually. Glycol is important to the level of freeze protection and the coolant’s boiling point. Over time, the water can evaporate from the system and increase glycol concentration, throwing off the coolant’s balance. Perform fluid analysis once a year for best performance. We offer that service through Oil Analyzers Inc. (www.oaitesting.com). We also offer antifreeze test strips (G1164).

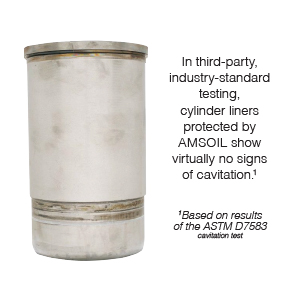

AMSOIL coolants effectively protect cylinder liners against cavitation erosion/corrosion pitting, without the problems associated with nitrite technology. Nitrites can cause aluminum corrosion, and they are being banned from coolants used by a growing number of manufacturers in both the heavy-duty and automotive markets. AMSOIL coolants feature top-performing technology that performs extremely well in ASTM D7583 (John Deere Cavitation Test) testing.

• Excellent protection against corrosion, cylinder-liner cavitation, freezing and boil-over.

• Virtually eliminates scaling problems.

• Maximum protection in extreme temperatures and operating conditions.

• Long-lasting protection for up to 1,000,000 miles (1,600,000 km), 20,000 hours or 8 years, whichever comes first, in heavy-duty applications.

• Ethylene glycol 50/50 pre-mix formulation.

• Excellent protection against corrosion, cylinder-liner cavitation, freezing and boil-over.

• Virtually eliminates scaling problems.

• Maximum protection in extreme temperatures and operating conditions.

• Long-lasting protection for up to 1,000,000 miles (1,600,000 km), 20,000 hours or 8 years, whichever comes first, in heavy-duty applications.

• Propylene glycol concentrated formulation – requires mixing with distilled or high-quality water.

*All trademarked names and images are the property of their respective owners and may be registered marks in some countries. No affiliation or endorsement claim, express or implied, is made by their use.

Comments

AMSOIL Lead Technical Writer for more than two decades.

Share: