Many ATVs and UTVs have a CVT, or continuously variable transmission. It allows the engine to operate at optimum power and efficiency in varying conditions. It does this by changing the gear ratio based on speed, rpm and load. Check out the video to see how an ATV CVT transmission works.

What goes on inside an ATV CVT transmission while you’re hard at work?

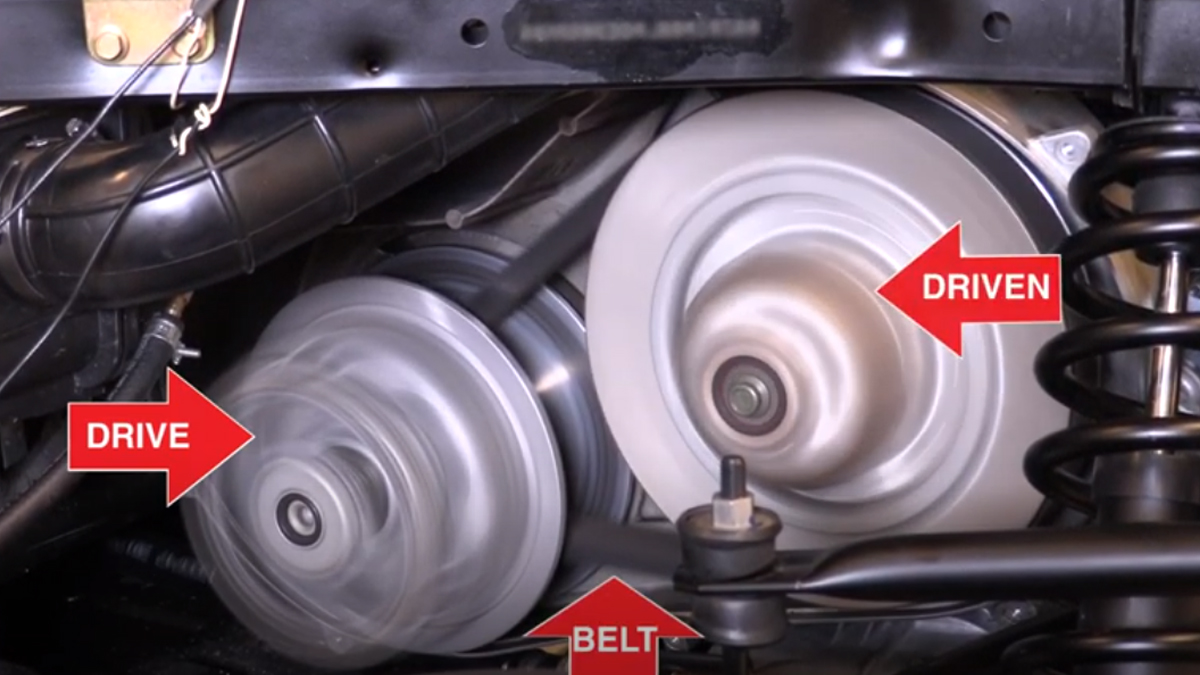

The CVT has three basic components:

- Drive pulley connected to the engine

- Driven pulley connected to the transaxle

- Belt

Each pulley has weighted sheaths that move in and out due to centrifugal force. This changes the diameter of the pulley. The belt constantly moves back and forth to create the ideal gear ratio, much like a bicycle. It works just like the CVT in a car.

In the video above, you can see how the pulleys change diameter depending on conditions, causing the belt to either rise or fall in the grooves.

When you depress the throttle, the drive pulley narrows and the driven pulley widens, creating a higher gear ratio. This allows you to reach higher speeds when flying across a field or down a trail.

When you let off the gas, the drive pulley widens and the driven pulley narrows, creating a lower gear ratio. When you’re hard at work, the drive pulley senses the increased load and narrows, creating a lower gear ratio. This gives you the torque needed to get the job done.

Your ATV’s CVT transmission is sophisticated. And, while the CVT itself doesn’t require lubrication, the transaxle does. With CVT replacement costs of $2,500 or more, it pays to protect your ATV/UTV transmission.

Check out the AMSOIL Extreme UTV test video or buy AMSOIL synthetic lubricants for your ATV/UTV. They’re formulated with durable synthetic base oils and premium additives to provide upgraded protection compared to lubricants formulated for standard service.

Comments

Share: