Internal combustion engines require air to make power. The more air ingested, the more fuel can be burned and the more power it can generate. Sometimes an engine just needs a little air intake boost to increase performance. Both turbochargers and superchargers work by using forced induction to drive compressed air into engine cylinders and generate more power.

What is a turbocharger?

Turbochargers use exhaust gases to drive a turbine, which spins a compressor that pushes more air into the engine cylinders. More air allows the engine to burn more fuel, which creates more power.

Why use a turbocharger?

Engineers have several options for increasing the amount of air that enters an engine’s cylinders. Turbocharging has emerged as the favorite in production vehicles, and it’s easy to understand why.

A turbocharged, direct-injected engine can make as much power as a naturally aspirated engine with two additional cylinders. Turbocharging with 6 to 8 pounds of boosted air pressure can result in torque increases over the same naturally aspirated engine of 40% or more. That also translates into as much as 150 additional horsepower.

Consider, for example, America’s best-selling Ford F-150* truck. A model equipped with a 3.5L EcoBoost V6 engine makes 375 horsepower, just 10 ponies shy of the same truck with a non-turbo 5.0L V8. However, the EcoBoost V6 makes 83 lb.-ft. more torque and has better fuel economy.

Equivalent power from smaller, lighter engines is why automakers are leaning heavily on turbos. In combination with direct fuel injection and variable valve timing, turbos help meet increasingly strict fuel economy and emissions requirements.

Disadvantages of turbocharging

Turbo lag: When you press the accelerator in a turbocharged vehicle, the engine takes a moment to create the exhaust gases that spin (or spool up) the turbo. The slight hesitation can feel like an eternity when you are expecting instantaneous power.

Complexity: Turbochargers are more complex to install and harder to maintain as they are connected directly to the exhaust system rather than the engine. Additional components may include intake piping, a boost controller, intercooler, downpipe, knock sensor and/or high-capacity fuel pump.

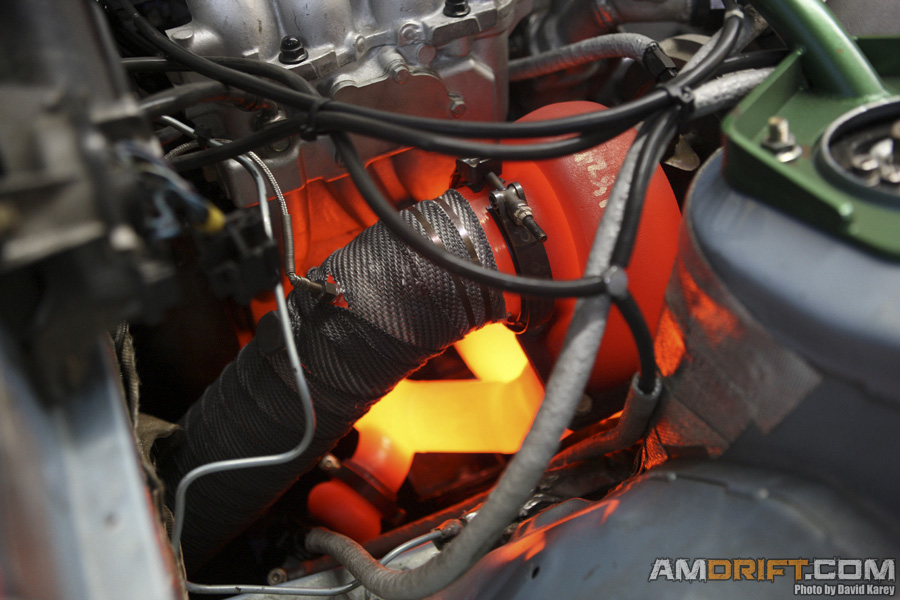

Heat: The exhaust gases that drive a turbo can exceed 1,000ºF and spin the turbine up to 150,000 rpm. This tremendous heat and stress can cause conventional oils to breakdown faster.

Lifespan: After heat and stress breakdown the lubrication, it forms harmful bearing deposits, known as turbo coking, which causes turbos to suffer reduced performance or fail altogether. The average turbocharger needs to be replaced before the engine, but turbo failure could potentially damage the engine, as well.

Cooldown: After operating at speed, it is recommended to run a turbocharged engine at low idle for a few minutes, giving the turbo a chance to cool down before shutting off the engine. Not allowing this cooldown period can cause additional coking and wear on the turbo and lead to premature failure.

Turbochargers use exhaust gases to drive a turbine, which spins a compressor that pushes more air into the engine.

What is a supercharger?

A supercharger uses power from the engine’s crankshaft to run a compressor that forces more air into the engine cylinders. Common methods of driving a supercharger include belt, gear, chain or direct drive. There are also superchargers that use an electric motor rather than mechanical power from the engine.

Why use a supercharger?

Superchargers are more responsive and provide immediate power delivery, eliminating the effects of turbo lag altogether and delivering instant boost, even at low rpm. In fairness, modern turbocharged engines are so well designed that manufacturers have nearly eliminated turbo lag, but they still require higher engine speed than a supercharger to create power. A supercharger added to a normally aspirated engine can create more usable power than a turbocharger.

Positive displacement vs. dynamic

The two main types of superchargers are primarily differentiated by the method of air transfer

Positive displacement superchargers deliver a near-constant level of boost pressure at all engine speeds using pumps that deliver a fixed volume of air per revolution of the compressor. These designs are typically up to 50% efficient at high boost levels and make more power at low rpm. Common types of positive-displacement superchargers include Roots, rotary-screw (Lysholm), sliding vane and scroll-type.

Dynamic superchargers create exponential increases in boost with increased engine speed by accelerating air to high speed and exchanging that velocity for pressure, which can be up to 85% efficient, but power output is reduced at lower engine speed. Multi-stage axial-flow and variable-ratio centrifugal are the most common types of dynamic compressor.

Disadvantages of supercharging

Bulk: The size and power requirements of a supercharger are impractical for most smaller engine daily drivers, so they are primarily installed in high-performance vehicles and hot rods rather than in production vehicles.

Efficiency: Because superchargers require engine power to operate, they create a parasitic horsepower loss, are less fuel efficient and create greater emissions.

Cost: Superchargers are typically custom-built for a specific vehicle. Since they are not mass-produced or included on most new vehicles, they can be difficult to acquire, and upfront cost and replacement parts can be expensive.

Comments

AMSOIL Technical Writer and 20-year veteran of the motorcycle industry. Enjoys tearing things apart to figure out how they work. If it can’t be repaired, it’s not worth owning.

Share: