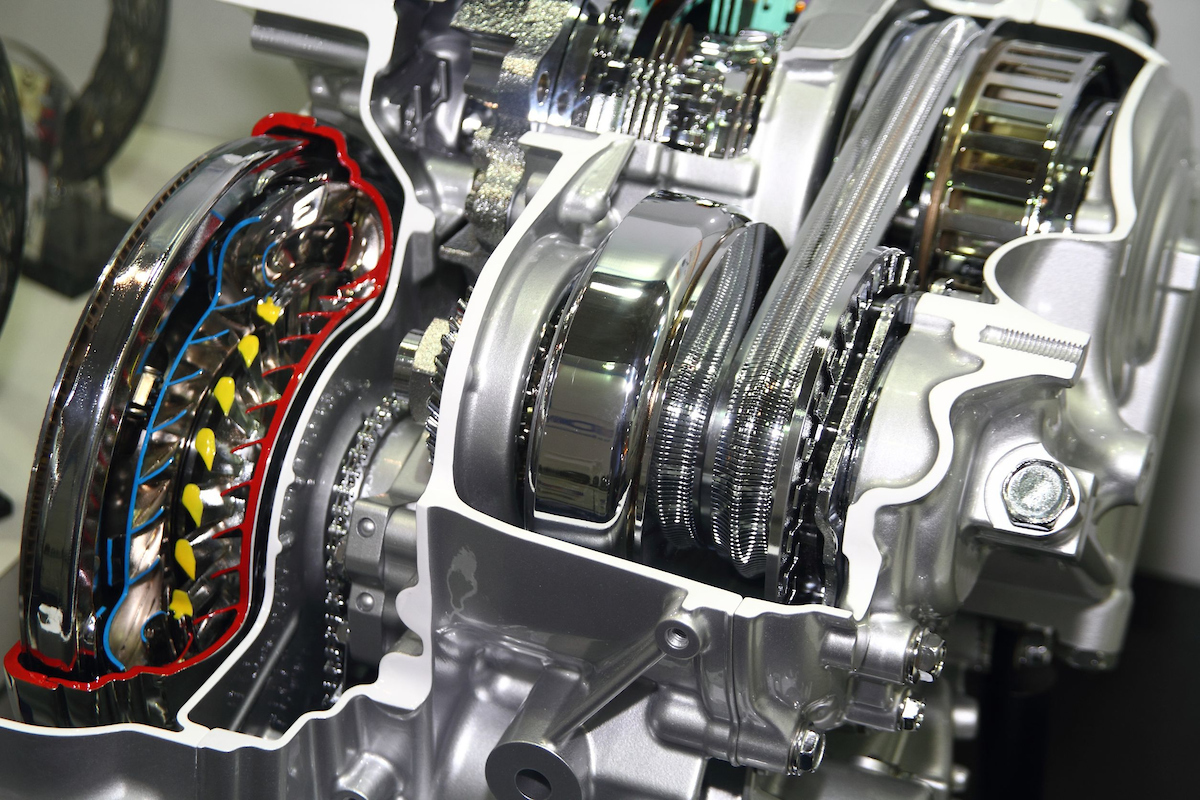

“CVT” is an acronym for Continuously Variable Transmission. A CVT uses a pair of variable-diameter pulleys and a belt or chain to provide unlimited gear ratios. CVTs are gaining popularity due to their efficiency but they require dedicated CVT fluid to maximize their performance and life.

How does a CVT work?

First, consider a traditional automatic or manual transmission, typically built with three to six fixed gears (plus reverse). These transmissions operate in one gear at a time and a slight surge from the difference in power transmitted can often be felt with each gear change.

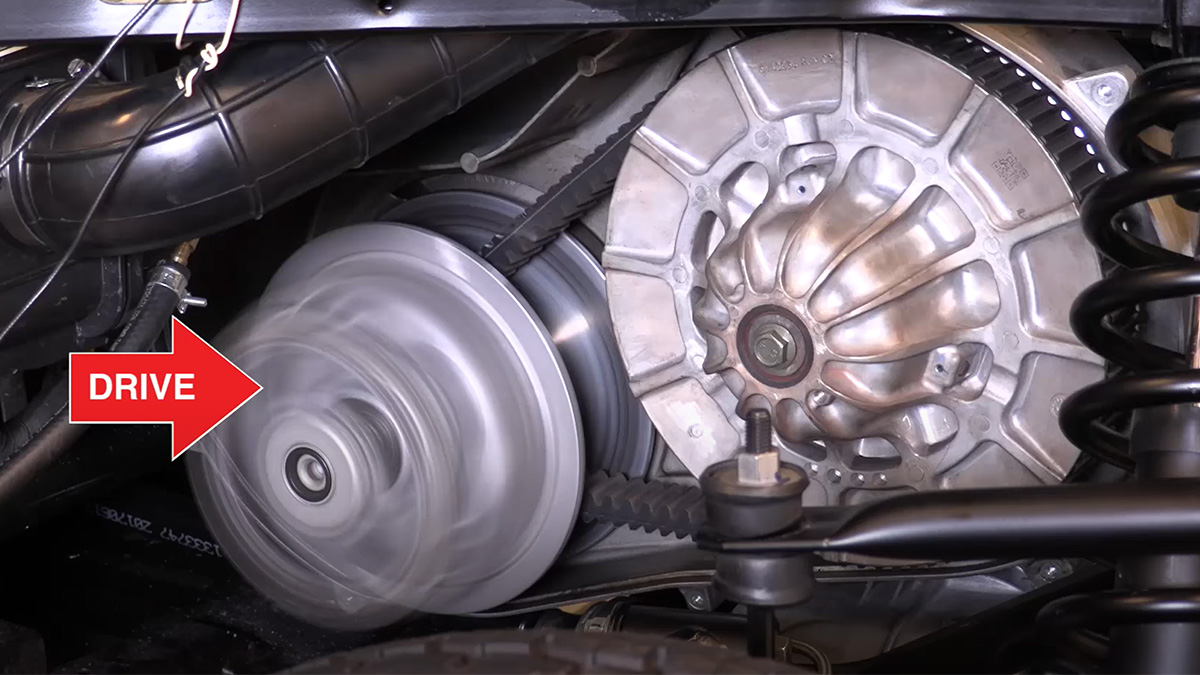

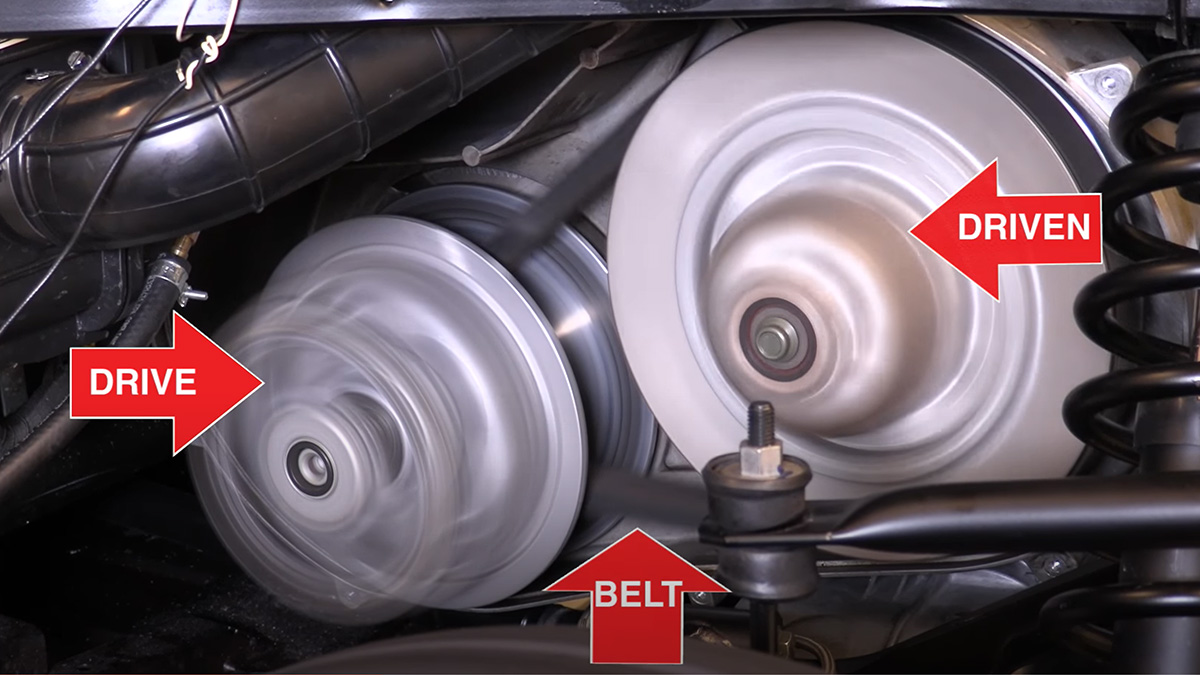

In contrast, CVTs offer unlimited gear ratios via a belt or chain connecting two pulleys that control power transmission from the engine to the wheels. The belt is designed with a series of V-shaped grooves that match the shape of the pulleys and changes the effective gear ratio by moving closer together or farther apart. As the pulley diameters change, the belt moves along the groove, allowing the transfer of rotational force from the input pulley to the output pulley.

A CVT allows the engine to always operate at its most efficient speed. A hydraulic pressure or electronic control system uses input from throttle position, engine speed, vehicle speed and other sensors to control the movement of the pulleys and determine the optimal gear ratio for the current driving conditions. The gear ratio is lower when the pulleys are closer, for better power and acceleration. The gear ratio is higher when the pulleys are farther apart, for better fuel economy at higher speeds.

The first CVT was developed for sawmills in 1879, and there have been several variations of CVT design. While the fundamental principles are the same, the mechanisms and components may differ, with more advanced modern systems using a computer to read the sensors and adjust pulley sizes.

CVT pros and cons

CVTs are becoming more common primarily due to increasingly restrictive environmental regulations that benefit from a CVT’s advantages over traditional automatic transmissions, including:

- Improved fuel economy

- Smoother acceleration

- Lower emissions

However, CVTs also have some disadvantages, including:

- More expensive

- Lower reliability

- Noisier

- Less driver feedback

Overall, CVTs are a viable choice for fuel economy and smooth acceleration. However, it can also make the car less reliable and less fun to drive, including a “rubber-band effect” when you rev the engine, but it takes a moment for power to catch up. Additionally, most CVTs can’t handle the power and torque of a truck or SUV, especially when used to tow your boat or camper, which is why you find them mostly on smaller cars, and powersports vehicles like snowmobiles and UTVs.

Maximizing CVT life

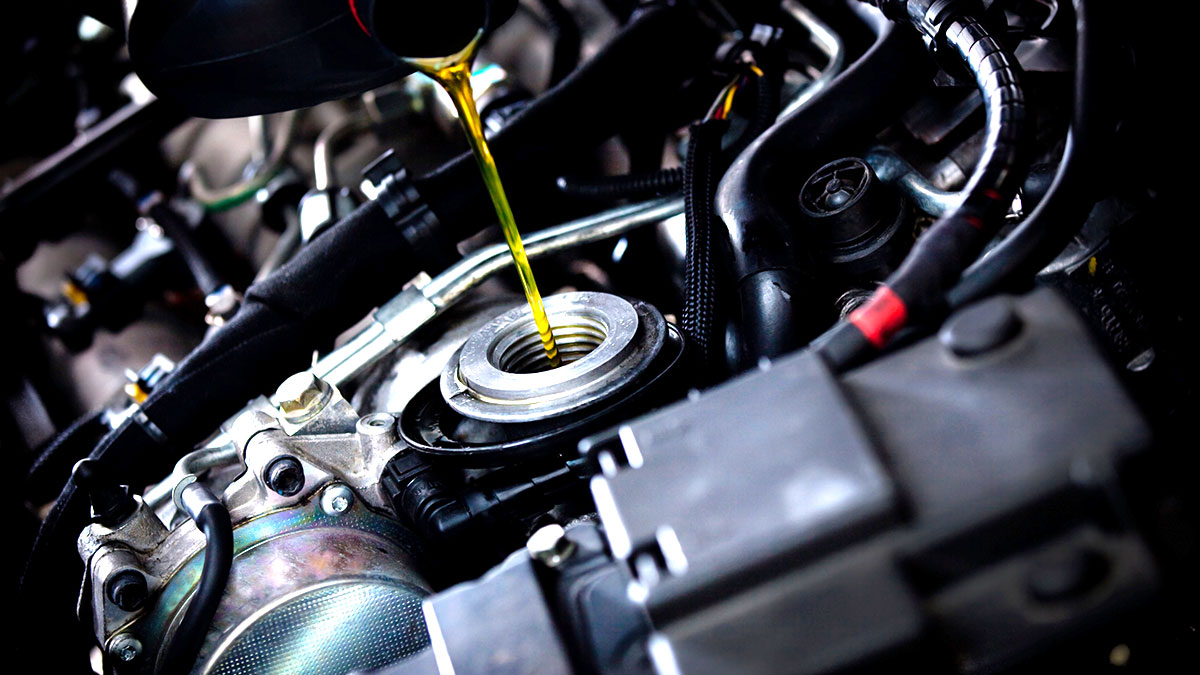

The transmission fluid ensures the belt or chain remains in contact with the pulleys, which is why CVTs require specialized fluids rather than traditional automatic or manual transmission fluid. CVT fluids are formulated with the correct frictional requirements to guard against belt slipping. Using the wrong fluid will reduce performance and potentially wreck your transmission.

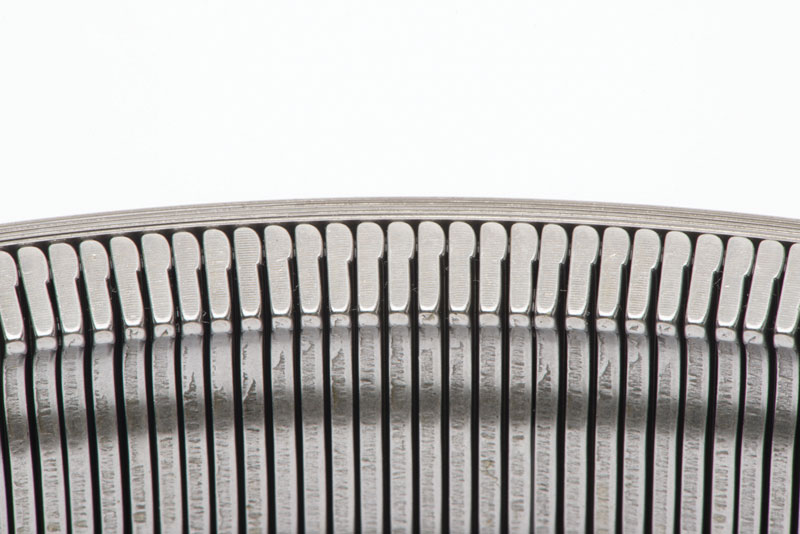

Wear protection is also vital to maximizing CVT performance and life. We designed AMSOIL Synthetic CVT Fluid to fight wear and help extend transmission life and field tested it against a prominent vehicle manufacturer’s CVT fluid for 100,000 miles. The steel CVT belt lubricated with AMSOIL Synthetic CVT Fluid demonstrated minimal wear, as you can see in the image above.

CVT failures can be expensive, so make sure to protect your CVT with premium AMSOIL Synthetic CVT Fluid. Learn more in the video below.

Comments

AMSOIL Technical Writer and 20-year veteran of the motorcycle industry. Enjoys tearing things apart to figure out how they work. If it can’t be repaired, it’s not worth owning.

Share: