Why should you upgrade your differential cover? It can help provide increased performance.

Although they’re not always top-of-mind for enthusiasts, differential covers play an important role in the performance of pickup truck differentials. In addition to providing access for changing gear lube, differential covers help dissipate heat that can damage differentials, and they protect gears from contaminants like dirt and water, as well as rocks and other large obstacles encountered when off-roading.

Enthusiasts seeking a performance boost and improved cooling often look toward the aftermarket for upgrades over their stock differential covers.

Upgrade your differential cover for better cooling

Enthusiasts love to push their trucks to the limit, but adding power and hauling heavy equipment add heat and stress to the differential. Keeping gear lube temperatures down is key to extending differential life, and performance differential covers can make a significant difference.

Features like cooling fins allow more surface area for oil cooling, while differential covers constructed of aluminum provide improved heat disbursement that keeps the differential and gear lube cool.

In addition, lighter aluminum differential covers are advantageous for competitors looking to shed overall vehicle weight.

Improved strength

Differential covers constructed of thin steel can dent, or they can bend and peel away from the differential when contacting rocks and other debris while off-roading, leading to gear lube leaking out and contaminants entering the differential and causing excess wear. Enthusiasts who put their pickups through the paces while off-roading often seek thicker, stronger differential covers constructed of heavy-duty iron.

Upgrade your differential cover for easier maintenance

Some performance differential covers include features designed to ease maintenance, including gear lube drain plugs and dipsticks. Some drain plugs and dipsticks include magnets, helping owners check for excessive wear without draining the gear lube.

Enhanced style

Upgrading a differential cover also offers the opportunity to add style to a pickup. Many differential covers are available with chrome-plating and polished aluminum for a beautiful finishing touch for customized trucks.

Look to the experts

With many different differential cover designs on the market, it is important for enthusiasts to find one that meets their specific needs. Experts like Banks Power specialize in this area and can provide professional guidance for enthusiasts seeking a performance upgrade.

Protect differentials with AMSOIL SEVERE GEAR®

Today’s vehicles produce substantially more horsepower, torque and towing capacity than their predecessors, yet the design of differential gears and bearings remains largely unchanged. Many differentials even use less gear lube and lower viscosities than before in an effort to reduce drag and increase fuel economy.

In essence, less gear lube is responsible for providing more protection.

Fighting the grind

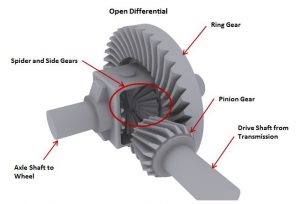

Differential designs have inherent weaknesses.

In a traditional automotive differential, the pinion gear concentrates intense pressure on the ring gear. As the gear teeth mesh, they slide against one another, separated only by a thin layer of lubricant.

The repeated stress the lubricant film bears can shear gear lubes, causing permanent viscosity loss. Once sheared, the fluid film weakens, ruptures and allows metal-to-metal contact, eventually leading to gear and bearing failure. The situation is amplified by severe-service applications like towing.

Thermal runaway

The extreme pressures and temperatures placed on gear lubricants can lead to a serious issue called thermal runaway.

As temperatures in the differential climb, some gear lubes lose viscosity and load-carrying capacity. When extreme loads break the lubricant film, metal-to-metal contact occurs, increasing friction and heat.

This increased friction and heat, in turn, results in further viscosity loss, which further increases friction and heat. As heat continues to spiral upward, viscosity continues to spiral downward. Thermal runaway is a vicious cycle that leads to irreparable equipment damage from extreme wear, and ultimately catastrophic gear and bearing failure.

AMSOIL SEVERE GEAR Synthetic Gear Lube

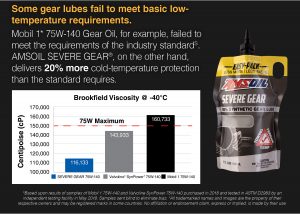

SEVERE GEAR excels in protecting gears and bearings from the rigors of severe-service operation. By design, it resists breakdown from high heat, preventing acids and carbon/varnish formation. Its wax-free construction also improves cold-flow properties, improving fuel economy and cold-weather performance.

• Superior film strength

• Controls thermal runaway

• Protects against rust and corrosion

• Helps reduce operating temperatures

• Maximum efficiency

• Long oil, seal and equipment life

• Flexible easy-pack for clean, fast installation

Comments

Share: