Grease is a solid to semi-fluid lubricant composed of a thickening agent dispersed in a liquid lubricant. It may also contain additional ingredients that impart specific properties, such as enhanced load-carrying capacity, corrosion resistance or thermal stability. Unlike liquid lubricants, grease is designed to stay in place — even on parts that move or are hard to reach. This makes it ideal for applications where regular re-lubrication isn’t practical.

Choosing the Right Grease

Consistency and base-oil viscosity are the most important factors to consider when selecting grease. Grease consistency is defined by the NLGI grade, which indicates how soft or firm the grease is. Softer grades like 000, 00 and 0 are semi-fluid and ideal for centralized lubrication systems, while NLGI #1 works well in colder climates or where pumping is difficult. NLGI #2 is the most commonly used grade, offering balanced performance for general-purpose applications. Harder grades, such as NLGI #3 and above, are suited for high-load or high-temperature conditions where leakage is a concern. Base-oil viscosity reflects the oil’s thickness — lower viscosities like ISO 68 are best for high-speed, light-load components like electric motors, while higher viscosities like ISO 460 are better for slow-speed, heavy-load applications such as gear couplings. Matching grease properties to your equipment’s speed, load and lubrication method ensures optimal protection and performance.

Compatibility Issues

Grease compatibility is a critical consideration when switching grease, as using incompatible greases can lead to performance issues and equipment damage. Compatibility primarily depends on the interaction between three components: the thickener, base oil and additive package. Different thickeners — such as lithium, calcium or polyurea — may not blend well, potentially causing the grease to soften, harden or separate. Similarly, mismatched base oils and additives can interfere with each other’s chemical stability and performance characteristics. The most common symptom of incompatibility is loss of consistency, which compromises the grease’s ability to lubricate and protect components. For questions about AMSOIL grease compatibility, contact AMSOIL Technical Services ([email protected], 715-399-8324).

Why AMSOIL Synthetic Grease

AMSOIL synthetic grease formulations use the highest-quality base oils and advanced additive packages that ensure…

• Superior load-carrying capacity for light- and heavy-duty applications.

• Excellent water resistance, even in washdown or marine environments.

• Outstanding oxidation stability for extended service life.

• Wide operating temperature ranges, from sub-zero to extreme heat.

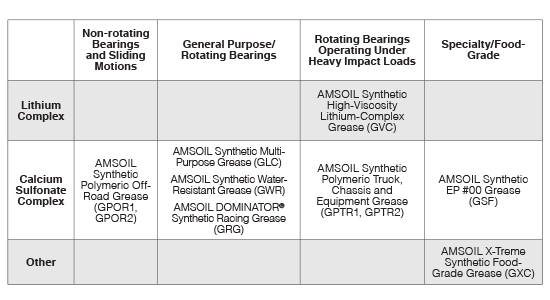

Which AMSOIL Synthetic Grease to Use

Whether formulated with a lithium complex, calcium sulfonate, aluminum complex or other thickener, each AMSOIL synthetic grease is rigorously evaluated to meet our high performance standards and real-world demands. Dealers can confidently recommend our greases to a wide range of enthusiasts, contractors and DIYers.

Do not assume one grease fits all. For optimum performance, it’s best to use a specialized grease designed for the application. Key factors to consider include the following:

1. Application

Rotating bearing, pivot bushing, two pieces sliding together?

2. Operating Environment

Inside or outside, wet or dry, hot or cold, dusty or clean?

3. Bearing Speed

High speeds (>10,000 rpm), low speeds (<10,000 rpm), sliding or non-rotating?

4. Bearing Load

Heavy, light, impact?

5. Manufacturer Recommendations

NLGI grades, thickener, tacky or non-tacky, OEM specifications?

Use the table below as a guide for selecting the proper AMSOIL synthetic grease based on application. For questions about AMSOIL grease recommendations, contact AMSOIL Technical Services ([email protected], 715-399-8324).

Comments

AMSOIL Market Manager Automotive and Heavy Duty has a decade of experience in sales, marketing and storytelling withing the oil industry.

Share: