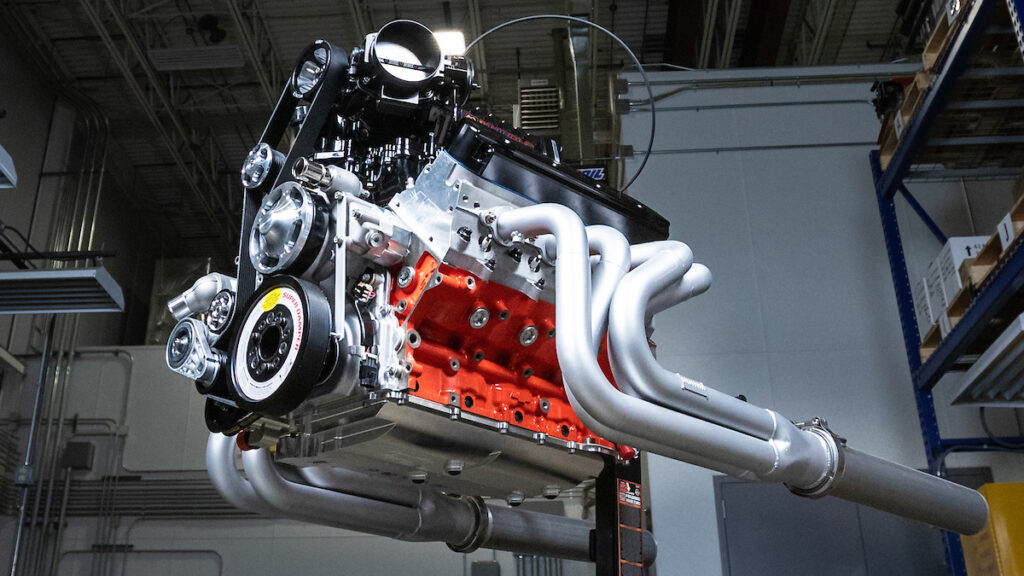

As an amateur racer and manager of the AMSOIL Mechanical Lab, Chris Orr knows a thing or two about performance. We caught up with him to learn more about his background and his 1,000-horsepower LS engine build.

Racing

LT: Let’s start with some background on your racing endeavors. What inspired you to consider racing?

CO: My older brother’s influence, mostly. He was always very mechanical; I was not. But I was always trying to keep up. Still am.

LT: When did you start racing?

CO: In 1987, I bought a 1974 Pontiac Firebird from a student at the University of Minnesota, Duluth. He was originally from California and had driven the car here to go to school. It had a 350 Pontiac with a smog pump. In 1988, that engine came out and a 455 Pontiac went in. That was where it started.

LT: What kind of racing do you do?

CO: The car is built to participate in any heads-up event with limited track prep, ideally against other original wheelbase, “steel roof and quarters,” big-tire cars. I run at tracks in the Midwest that hold events with classes the car qualifies for.

LT: What vehicle are you racing these days?

CO: A 1967 Firebird with 3/4 tube chassis, SFI 25.2 certified with the original VIN tag.

Team AMSOIL

LT: What is your role at AMSOIL?

CO: My title is Mechanical Lab Manager. I work with technicians and engineers to design tests, build and carry them out, then review and report the results. Our work includes validating oil products or materials through proof of performance and comparative evaluations in whatever platform that product or material is typically used in.

Examples could be anything that uses a lubricant, including two-stroke or four-stroke powersports, lawn and garden equipment, air compressors, transmissions, automotive engines, etc.

LT: How does experience from the track translate to the mechanical lab?

CO: Mechanical assemblies share similarities, as do good processes. So conscientious application based on the previous experiences of our group is how we get things done.

Building the LS

LT: What was the most challenging part of building the LS?

CO: I don’t know that anything was ‘most’ challenging. I hadn’t spent much time with the Holley engine management system we used, so that required some accelerated learning to be sure we could perform the desired testing effectively.

LT: What was the most rewarding part of building the LS?

CO: Not encountering a single significant issue or setback from start to finish – either good planning or dumb luck, I suppose.

LT: If you didn’t have to follow the rules, what would you have done differently?

CO: Pump gas is always a risk factor and a limitation. I don’t equate high performance with the cheapest fuel available. Personally, I would never approach a project that way. But 91 octane was the rule, so the engine was built to produce the 1000-horsepower target safely on that fuel.

AMSOIL Inside

LT: What AMSOIL products did you use?

CO: During the build we used the AMSOIL products wherever possible, including:

- AMSOIL Engine Assembly Lube,

- AMSOIL Brake and Parts Cleaner,

- AMSOIL Break-In Oil

- AMSOIL DOMINATOR® Synthetic Racing Oil.

The objective was to validate those products’ ability to properly protect the engine at the target power levels desired, which they did.

Head over to the AMSOIL YouTube channel to see Chris’s complete 1000-horsepower LS engine build and proof of performance testing.