Cylinder-liner cavitation, corrosion, scale and other problems can sideline your diesel and cause expensive problems. It’s the engine coolant’s job to prevent these problems. But, for those using most conventional coolants, it’s the operator’s job to add a diesel coolant additive, also called a supplemental coolant additive (SCA), to the system halfway through the service interval.

Overlooking this vital step leaves your diesel’s cooling system susceptible to the problems listed above.

What does a diesel coolant additive do?

To understand why most conventional coolants require use of an SCA, let’s quickly look at how engine coolant is made.

Coolant consists of a base (typically ethylene glycol or propylene glycol) mixed with additives and water. The base is primarily responsible for keeping your engine from freezing in winter and overheating in summer.

The additives guard against corrosion, cavitation and scaling, while the water helps remove heat from the engine.

Additives are sacrificial in nature, meaning they deplete over time as they do their job.

Once additives deplete, however, all kinds of problems can arise, like cylinder-liner cavitation, corrosion and formation of scale, which reduces heat-transfer and can lead to engine overheating.

Supplemental diesel coolant additives replenish the additives that have depleted to ensure your engine is still protected.

The pitfalls of supplemental diesel coolant additives (SCA)

Adding an SCA midway through the coolant service interval sounds like a decent solution, but it has drawbacks.

For starters, it’s easy to overlook. Life can get in the way of our best-laid maintenance plans, putting our vehicles at risk.

Secondly, they’re a hassle. You have to test the coolant using test strips and match the color of the strip to a chart. Some of these charts look like they require an advanced chemistry degree to decipher.

I’ve also seen online SCA calculators that help determine the correct amount of diesel coolant additive you need. I just want to get back to driving, not worry if my math is correct.

When using test strips, you’d better correctly match it with the chart, or you risk adding too much SCA, which can cause additive “dropout.”

This occurs when the additives separate from the coolant base and form radiator sludge and slime that plug coolant passages. Too much SCA can also lead to scale buildup, which inhibits heat-transfer.

Adding too little SCA is just as bad; it can leave your engine vulnerable to scale, corrosion and cavitation.

Find out if automotive coolant additives really work.

How cylinder-liner cavitation occurs

Cavitation is one of the most expensive problems heavy-duty diesels can face. Here’s how it occurs.

Most diesel engines are designed with replaceable cast-iron cylinder liners that are pressed into the engine block. While this doesn’t apply to turbodiesel pickups, it affects heavy-duty over-the-road trucks and other diesels.

The piston moves up and down inside the liner while a jacket of coolant surrounds the outside of the liner to cool the engine. When the engine is running, the pistons move vertically inside their liners several thousand times per minute.

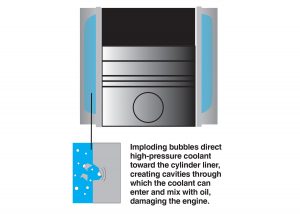

Meanwhile, the rotary motion of the crankshaft applies a thrust force through the connecting rods to the piston. These contradictory movements cause the pistons to hammer the liners, causing significant vibration, similar to the effect of ringing a bell.

This vibration can cause air bubbles to form in the coolant surrounding the liner. When the bubbles rupture, they direct a high-pressure stream of coolant at the liner. Like a rushing river carving away a canyon wall, the coolant can erode the liner until cavities form.

Left unchecked, these cavities can keeping growing and eventually penetrate the liner, allowing oil and coolant to mix.

Once that happens, it’s only a matter of time before the engine fails.

Fighting liner cavitation the old way

For years, formulators have added metallic salts, like nitrites and molybdenates, to coolant that attach themselves to the liner and form a sacrificial layer.

When the coolant bubbles implode, the metallic salts absorb the pressure and break off from the liner surface rather than the metal itself.

As we’ve seen, metallic salts naturally deplete over time, meaning you must replenish them periodically by adding a supplemental diesel coolant additive.

Fighting cavitation the new way

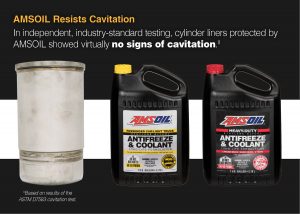

The trend in the coolant market – and the strategy we use at AMSOIL – is to eliminate adding an SCA by formulating coolant with hybrid organic acid technology (HOAT).

The chemistry of HOAT coolants passivates the liner surface, which coats it in a thin inert layer that provides protection against cavitation and corrosion.

Unlike old-fashioned metallic salts, the additives in HOAT coolants last much longer, meaning you don’t have to replenish the system with an SCA.

Check out how AMSOIL Heavy-Duty Antifreeze & Coolant and Passenger Car & Light Truck Antifreeze & Coolant prevent cavitation and corrosion in industry-standard testing.

Answering the question…

So, do you need to use a supplemental diesel coolant additive (SCA)?

Not if you’re using AMSOIL antifreeze & coolant.

For you heavy-duty operators, Heavy-Duty Antifreeze & Coolant delivers excellent protection against overheating and corrosion for up to 1 million miles (1,609,344 km), 20,000 hours or 8 years, whichever comes first. And it eliminates the hassle of adding an SCA.

For passenger car/light-truck owners, Passenger Car & Light Truck Antifreeze & Coolant eliminates additive drop-out, scaling and other issues inherent to conventional “green” coolants. It’s pre-mixed 50/50 with high-quality water and lasts up to 150,000 miles or 5 years.

For those who want a low-toxicity, biodegradable coolant, we offer AMSOIL Low Toxicity Antifreeze & Engine Coolant. It delivers excellent protection for up to 150,000 miles (241,000 km) or 5 years, whichever comes first in passenger cars and light trucks. In heavy-duty applications, it lasts 1 million miles (1,609,344 km), 20,000 hours or 8 years, whichever comes first, and is compatible with all ethylene and propylene coolant colors.

Comments

Share: