The shelves at your local parts store are full of aftermarket engine oil additives, such as stop-leak products and oil treatments, that promise several benefits, including better wear protection, longer oil life, reduced oil consumption, increased oil pressure and increased fuel economy. Do these engine oil additives work? Are aftermarket top-treat engine oil additives good or bad?

To find out, we bought a couple of the most popular engine oil additives on the market and used them to treat a brand-name conventional 5W-30 motor oil. Using industry-standard testing, we wanted to see if the additives, indeed, provided the promised benefits. Scroll down to see the results.

What are aftermarket top-treat engine oil additives?

First, however, let’s define our terms. What is a top-treat engine oil additive? And why do some motorists use them?

Engine oil additives are often high-viscosity base oils or additives designed to augment the motor oil formula. They’re supposed to improve the formulation in a particular area and provide additional benefits to you, such as better wear protection, reduced oil consumption and so on. They’re often designed and marketed to help solve a problem you might be having with your engine, such as excessive oil consumption.

While additive manufacturers maintain their formulations as proprietary, making it difficult to know exactly what you’re buying, some additives have advertised materials like Teflon, molybdenum or graphite. Some have used chlorine, which can be highly corrosive when mixed with water, a common oil contaminant due to condensation or the effects of ethanol in fuel.

Why use a top-treat engine oil additive?

Some motorists have noble reasons for using oil additives.

Say your truck is burning oil. It’s likely the piston rings or valve guides have worn out, which allows excessive oil to enter the combustion chamber and burn. Overhauling the engine is expensive and may not be worthwhile in a high-mileage vehicle that’s seen its best days.

Wouldn’t you rather buy a relatively cheap additive and cross your fingers that it works than visit a mechanic to have the problem fixed?

Or, maybe you have a newer vehicle and you want to maintain it for the long haul. An engine oil additive that promises improved wear protection sounds like a great way to ensure your engine lasts for years and continues to make the power you want. You’re doing a little something extra for your engine, which is a noble endeavor.

Do engine oil additives work?

Your intentions may be good, but is the additive’s performance?

It’s unlikely that motorists who use a top-shelf synthetic oil are going to augment it with an aftermarket additive, so we opted to use a name brand conventional 5W-30 motor oil that’s readily available at any auto parts store.

We subjected the conventional motor oil to a few different industry-standard bench tests to gauge wear protection, cold-flow ability and viscosity stability. Having established the oil’s baseline performance, we then treated samples of the same conventional oil with two popular additives according to the treat rates on their labels. Then we tested the oil again.

What did we find?

For starters, our findings show that conventional oil treated with the two additives we tested did provide better wear protection in bench testing compared to untreated oil.

But it came with a big tradeoff.

We also found that the additives impaired the oil’s cold-flow ability and increased its viscosity so much that it no longer met the viscosity requirements of a 5W or a 30-weight oil.

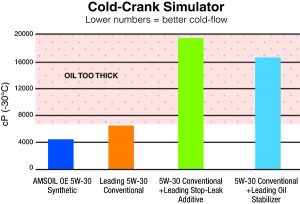

In the graph below, notice the orange bar, which shows the untreated oil’s performance in the Cold-Crank Simulator (CCS) Test (ASTM D5293). This test is used to determine an oil’s ability to flow well during cold starts, which helps prevent dry starts and protect against wear. The untreated oil falls within the acceptable range for a 5W oil (6,600 cP max. @-30°C). The performance of AMSOIL OE 5W-30 Synthetic Motor Oil is also included for a comparison (the dark blue bar on the left), which demonstrates the improved cold-flow characteristics of quality synthetic motor oil.

Now look at the conventional oil’s performance in the CCS Test after having been treated with the engine oil additives. Both the stop-leak additive and the oil stabilizer increased the oil’s viscosity so much that both samples no longer meet the requirements of a 5W oil, failing the test. This means the oil won’t flow as readily at startup, impairing wear protection at the time when most wear occurs.

It’s important to note that cold-flow isn’t just for us northern folks. Cold to your engine is any temperature below normal operating temperature, which is about 212°F (100°C). The better the oil flows after the engine has sat for an extended period, like overnight in your garage, the better it will protect against wear. While especially true at -22°F (-30°C), the temperature at which the CCS Test is performed for 5W oils, it’s also true at 80°F (17°C) or warmer.

The cold-pour test shown in this video offers confirmation. We cooled samples of the conventional oil alone and treated with the two leading additives to -40°F. Take a look.

You can clearly see that the oil treated with the engine oil additives flows more slowly. The oil treated with the leading oil stabilizer turned into a gelatinous blob and took about two minutes to flow. Imagine if that oil were in your engine, especially if you live in a cold climate. It wouldn’t flow at startup, particularly through the tiny oil passages in the crank journals and camshaft. It also would fail to flow through the tiny opening in your variable-valve-timing solenoids, if your engine is so equipped, reducing performance and maybe triggering a check-engine light.

Over time, wear protection will suffer if you use these additives, and so will your engine.

What about the oil’s viscosity at operating temperature?

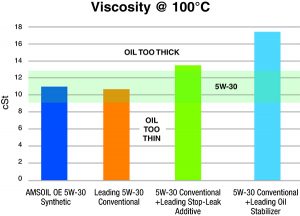

Here, too, the engine oil additives raise red flags. In this graph, the orange bar shows the viscosity of the untreated conventional oil at 100°C (212°F). It falls within range for a 5W-30 oil, shown by the green transparent area.

Now, look at the viscosity at 100°C of the oil treated with the two additives. That’s right…they’re both out of viscosity range. In effect, you’re now using a 40- or 50-weight oil instead of the 30-weight the engine manufacturer recommends.

So, what’s so bad about that?

Your engine is designed to use a specific viscosity of oil. Oil that’s too thick for the engine can fail to flow fast enough to fill the area between the crank journals and main bearings, leading to bearing wear. Thick oil also impairs circulation, reducing the oil’s ability to transfer heat from critical engine components. It also generates more heat due to increased internal friction while decreasing fuel economy.

Are engine oil additives good or bad?

Given what you’ve just seen, you can answer that question yourself.

While they appear to help improve wear protection in bench testing, the oil additives we tested come with severe tradeoffs that reduce long-term protection and performance.

You’re better off using a good synthetic oil to get the benefits of improved wear protection, reduced oil consumption, maximum fuel economy and more. Not only will it protect better, it’ll end up costing about the same once you factor in the cost of the additive. And it won’t come with the negative side effects we’ve seen here.

Shameless plug time: If you’re using or thinking about using an engine oil additive, consider AMSOIL OE Synthetic Motor Oil instead.

Comments

Share: