What are seals?

Seals often take the form of rings or gaskets, which join two surfaces together and must create an effective fluid barrier over long periods of time under extreme changes in pressure and temperature.

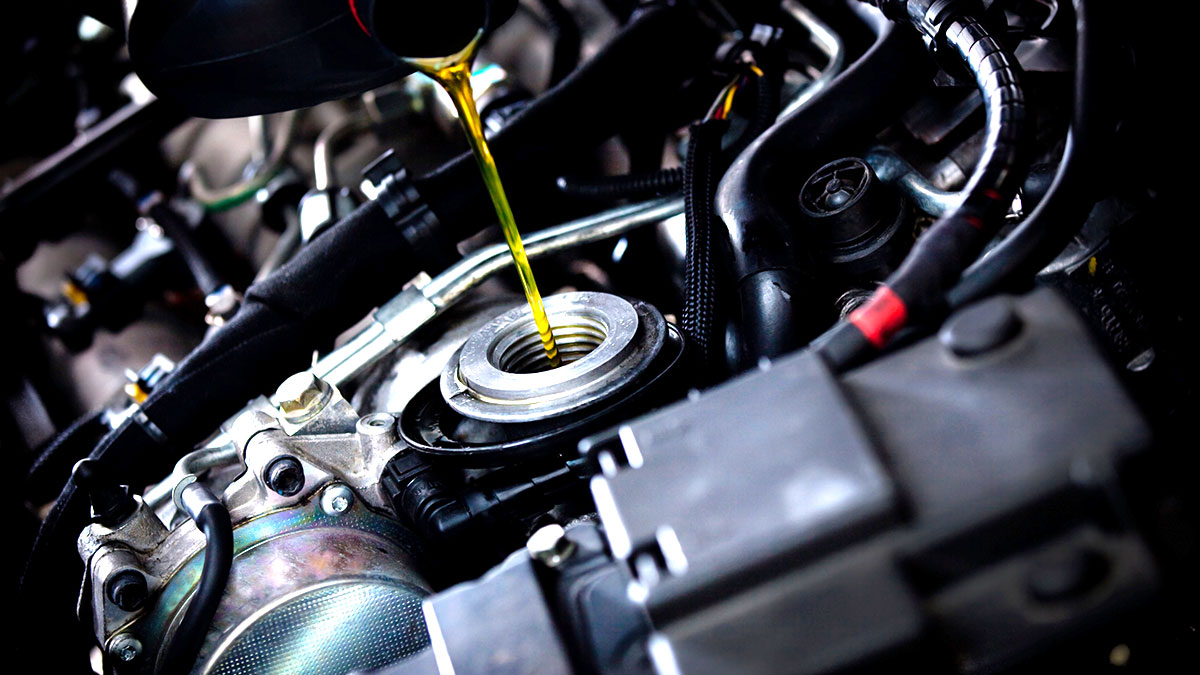

Most motorists don’t think about seals until they notice a fluid leak. Common seal locations include valve covers, crankshaft, transmission output shaft and axles. Vehicles contain many different seals, which are responsible for:

- Retaining fluids within the system

- Keeping contaminants out

- Keeping different fluids separated

- Confining pressure

When synthetic lubricants were first introduced, many people erroneously believed the oils were too slippery and leaked past seals. However, field studies and real-world use by countless motorists has proven otherwise.

A more common scenario is that switching to synthetic lubricants will clean internal components, washing away existing sludge and other contaminants, which could potentially be plugging leaky seals. Using synthetic lubricants from the start keeps internals cleaner and helps seals last longer.

Age, temperature, mileage and even storage can lead to seals shrinking, cracking or tearing.

What are seals made of?

In the 1930s, engineers pioneered the manufacturing of synthetic rubber, also known as elastomers. Made primarily of elastomers, modern seal materials offer enhanced performance in harsh environments.

Common automotive seal materials include nitrile, neoprene, silicone, ethylene acrylic, polyacrylate and fluoroelastomer. Each material offers different strengths and weaknesses throughout different temperature ranges (see list below).

Age, temperature, high mileage and storage can lead to drying and hardening of elastomers, causing shrinking, cracking or tearing. In addition to fluid leaks, damaged seals can allow dirt and other contaminants to enter the system, negatively affecting performance and increasing wear.

Nitrile seals, better known as buna-N (NBR), are common in automotive applications due to their low cost and good resistance to oil, water, grease and other substances. However, NBR offers poor resistance to ozone and weather aging. Ethylene acrylic and polyacrylate are often used in transmission and power-steering units.

Proper seal lubrication keeps fluids in and contaminants out of your vehicle.

Do seals require lubrication?

Wherever seals are installed and whatever they are made of, proper lubrication is required to maximize life and performance. Seal and lubrication compatibility is achieved by selecting the proper base oils and additives that cause seals to swell at a slow, controlled rate over their usable lives. This swelling allows the seal material to fill any gaps caused by worn material and prevent premature leakage.

Seal conditioners are added to lubricants to help keep seal materials supple and prevent them from becoming brittle and causing leaks. For example, valve seals prevent oil from entering the cylinder during the intake stroke. A dry, brittle seal may allow oil to leak past the seal and burn during combustion, causing the engine to consume more oil.

Comments

AMSOIL Technical Writer and 20-year veteran of the motorcycle industry. Enjoys tearing things apart to figure out how they work. If it can’t be repaired, it’s not worth owning.

Share: