The valvetrain plays a crucial role in your engine. It is the conductor orchestrating the precise opening and closing of engine valves, ensuring optimal airflow in and out of the combustion chamber. Far from the limelight of turbochargers and high-performance fuel systems, the valvetrain is the backbone of engine functionality, significantly influencing performance, efficiency and reliability.

What is it and How Does it Work?

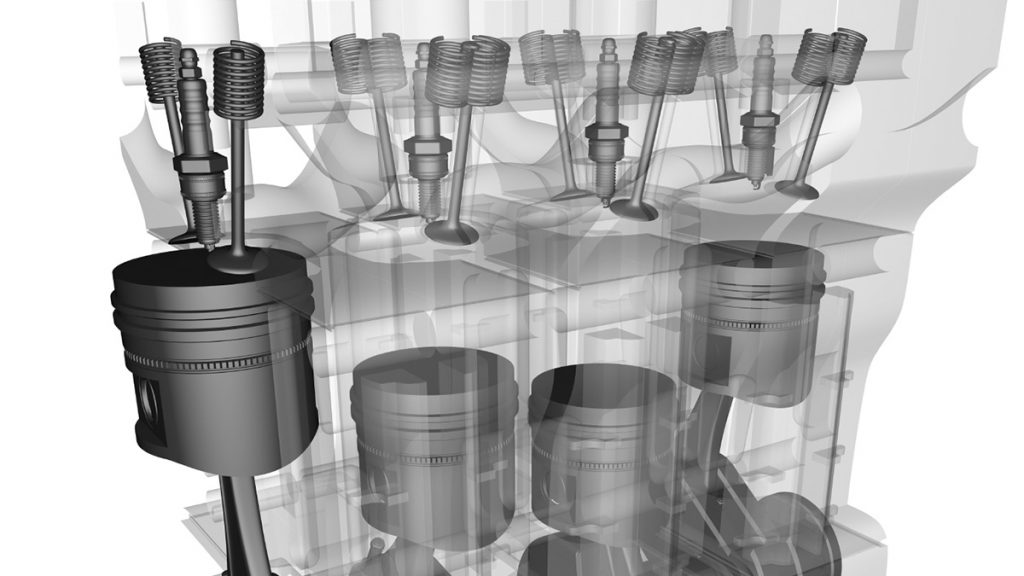

The valvetrain is a collection of components responsible for managing the timing of the engine’s intake and exhaust valves. Its primary function is allowing fresh air to enter the combustion chamber and expelling exhaust gases. This coordination is crucial as it dictates how effectively an engine can breathe, impacting power output and fuel efficiency.

At the heart of this operation is the camshaft, which controls valve movement through a series of lobes that push against other components to open and close the valves as it spins. The camshaft is synchronized with the crankshaft, ensuring that valve operation is perfectly timed with piston movement.

Valvetrain Components

The valvetrain is composed of several interrelated components, each performing a specific function.

Camshaft

The camshaft is a rotating shaft equipped with cam lobes shaped to control valve timing and lift. It is driven by the crankshaft, usually through a timing chain or belt. In overhead camshaft designs, the camshaft is positioned above the valves, directly actuating them without the need for pushrods. In pushrod engines the camshaft is located below the valves.

Pushrods

Pushrods are necessary in engines where the camshaft is in the block rather than the cylinder head. They are slender, metal rods that transfer motion from the camshaft to the rocker arms in overhead valve engines. It’s like a chain reaction: camshaft lobes lift the pushrods and pushrods lift the rocker arms. Much like a teeter-totter, when the rocker arms are lifted on one side, the other end pushes down against the valve springs to open the valves. We dive deeper into each component within this system below.

Rocker Arms

Acting as levers, rocker arms translate the linear motion of pushrods into the vertical movement needed to open the valves. Their configuration can affect valve lift and timing, influencing engine performance.

Rocker Shafts

Providing pivotal support, rocker shafts allow rocker arms to pivot smoothly as they actuate the valves.

Valve Bridges

In engines with multiple valves per cylinder, valve bridges connect paired valves, ensuring they open and close in unison for optimal airflow.

Valves

The intake and exhaust valves control the flow of air and fuel into and out of the combustion chamber. Their precise operation is critical for maintaining engine efficiency and performance.

Valve Springs

These springs ensure that valves close completely after opening, maintaining the pressure needed to keep them seated against the valve seat.