The job of the engine is to transform fuel into energy. So, how does an engine work? Internal combustion engines create energy by burning a fuel-air mixture under pressure inside the cylinder, and it’s converted into movement by the engine’s pistons, connecting rods and crankshaft.

However, the design and function of components varies depending on the primary purpose of the vehicle, fuel type and other considerations. Let’s start with the basics of combustion and engine design.

Four Functions of Combustion

Four-stroke engines must perform four essential functions to operate properly and efficiently:

-

• Intake

• Compression

• Power

• Exhaust

The intake function involves drawing a mixture of air and fuel into the combustion chamber. The compression function compresses the mixture. The power function involves igniting the mixture and harnessing the power of that reaction. The exhaust function expels the burned gases from the engine.

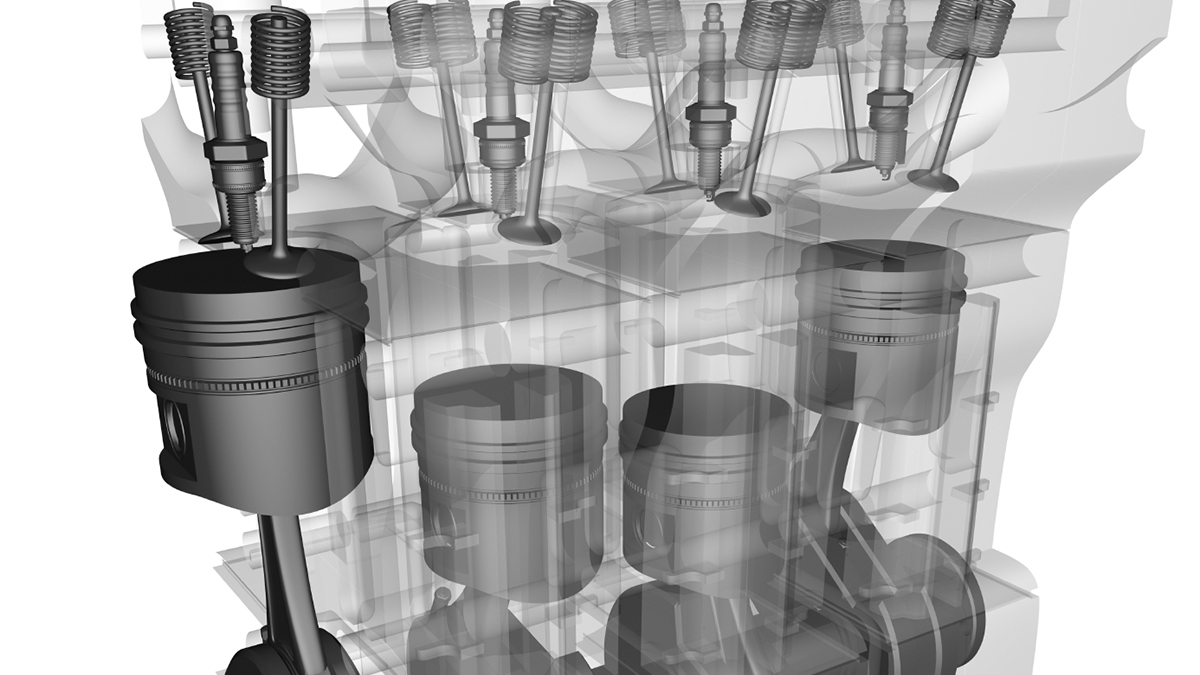

Piston and Piston Rings

The piston moves up and down, or reciprocates, inside the engine’s cylinder. In doing so, it helps complete the four functions of combustion, creating a vacuum that draws the fuel-air mixture into the combustion chamber (intake), compressing the mixture (compression), igniting it (power) and expelling the burned byproducts (exhaust).

The area above the piston is referred to as the cylinder or combustion chamber. Air and fuel are compressed and ignited in the cylinder. Piston rings below the piston crown form a seal against the cylinder wall to prevent fuel from leaking out of the combustion chamber and help prevent most of the combustion byproducts from leaking past the piston rings and contaminating the oil in the crankcase. The piston rings also help cool the piston by dispersing oil along the cylinder wall and transferring heat.

Connecting Rods and Wrist Pins

Connecting rods connect the piston to the crankshaft. A wrist pin is used to attach the piston to the connecting rod, allowing them to pivot as they reciprocate. Both the undercrown and wrist pin are exposed to extreme stress as they bear the force from the reciprocating pistons, most notably when the piston is driven down by the force of combustion.

How Does an Engine Work? Crankshaft

The crankshaft converts the pistons’ reciprocating action into rotary movement that is transferred to the transmission. In a typical consumer vehicle, the crankshaft is attached to the transmission via clutch (manual) or torque converter (automatic). In a lawnmower, the crankshaft is attached directly to the cutting blades.

Seals at the ends of the crankshaft prevent oil from leaking out of the engine. Seals in two-stroke engines have the added challenge of operating under the forces of positive and negative pressure created by the reciprocating piston. Four-stroke engine seals do not operate under such pressure.

Bearings

The engine’s main bearings support the crankshaft. Depending on the engine design, roller bearings or plain bearings may be used.

Roller bearings (anti-friction bearings) are used in two-stroke applications because a dedicated lubricant source is not available. Roller bearings contain moving elements and may also be referred to as roller-element bearings.

Plain bearings are fixed, non-moving bearings that provide support to the rotating crankshaft in four-stroke applications. They are designed to provide low-friction resistance and require a dedicated, pressurized lubrication source to provide an adequate fluid barrier between metal components.