Keeping equipment operating on the jobsite is vital for maintaining a successful business, but fuel contamination presents a common problem for excavators and other off-road equipment that constantly operate in dusty, dirty environments. Maintaining a clean and efficient fuel system is essential for avoiding costly downtime and premature equipment failure.

Common Fuel Contaminants

Water enters fuel systems through condensation in fuel tanks or exposure to rain and humidity. Water contamination can lead to corrosion and microbial growth.

Dust and dirt can enter the fuel system through unsealed fuel caps or poor fuel-storage and handling practices.

Gum and varnish form when diesel fuel oxidizes over time, coating fuel-system components and reducing efficiency.

Negative Effects of Fuel Contamination

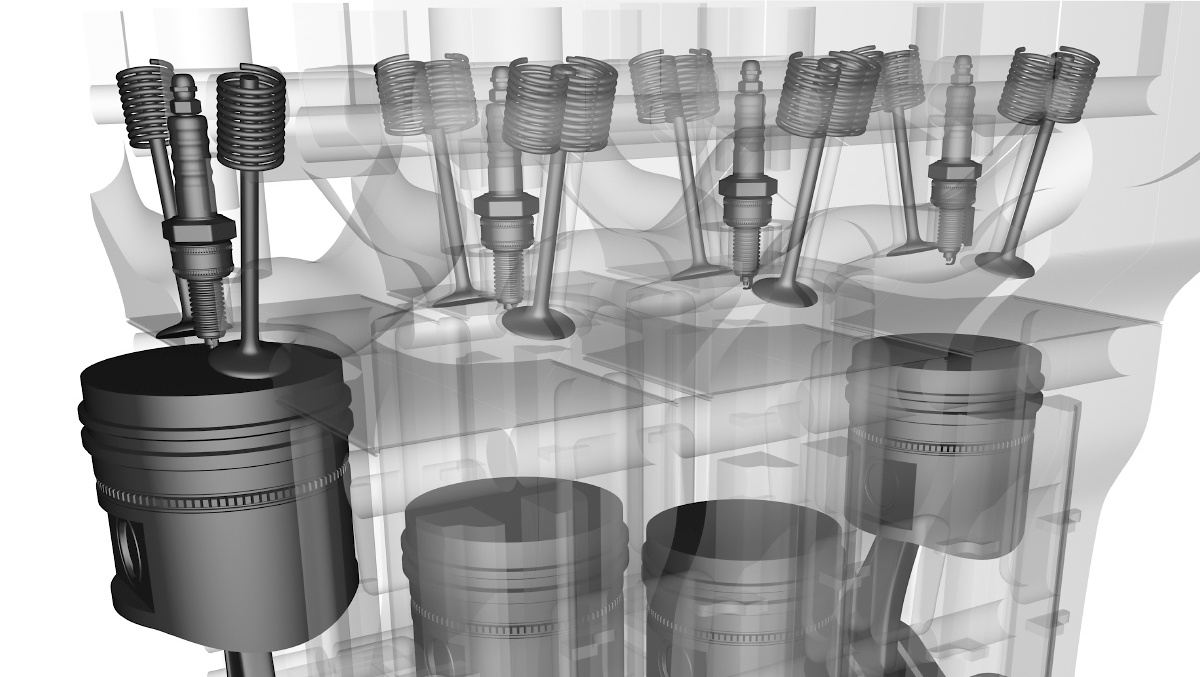

Fuel contamination increases wear on fuel injectors and other internal components, decreases equipment performance and leads to more frequent breakdowns and premature equipment failure. Early detection can save contractors time and money. Common symptoms of fuel contamination include the following:

Difficult Starts

Engines are tougher to start when contaminants obstruct fuel flow.

Reduced Power

Engines lose power and acceleration when dirty fuel affects combustion.

Black or White Smoke

Black or white exhaust smoke can indicate improper combustion caused by contamination.

Clogged Fuel Filter

Contaminants can clog fuel filters, leading to poor combustion and

power loss.

Corroded Fuel-System Components

Corrosion on injectors or tanks is often a sign of water contamination.

Preventive Measures

Fuel contamination can typically be blamed on environmental exposure, poor fuel-handling practices or degradation of the fuel itself. Taking steps to prevent fuel contamination is crucial for keeping excavators and other off-road equipment on the job.

Use High-Quality Fuel

Purchase fuel from reputable suppliers. Low-quality fuel is more likely to contain impurities that affect engine performance and life.

Store Fuel Properly

Store fuel in airtight, clean, weather-resistant containers. Frequently clean storage tanks and inspect for leaks or water ingress.

Drain Water Traps

Most excavator fuel systems are equipped with water separators. It’s important to drain these traps to prevent water buildup.

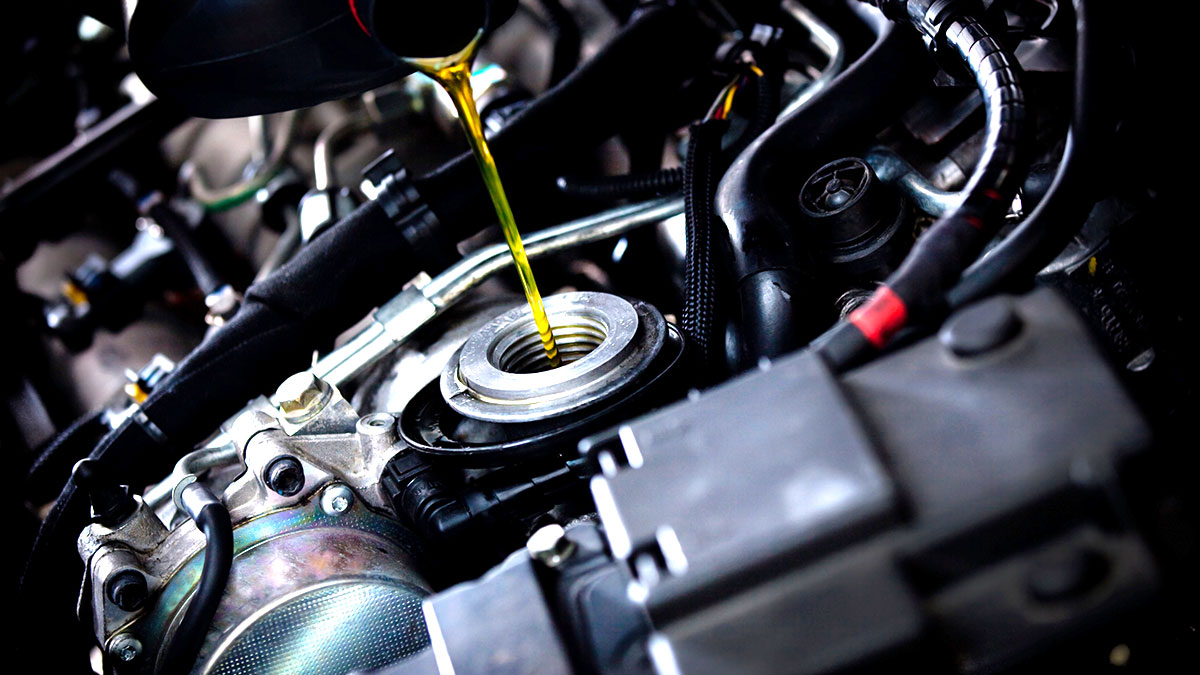

Change Fuel Filters

Fuel filters should be changed regularly to help maintain proper fuel flow and prevent contaminants from reaching the injectors.

Inspect the Fuel System

Inspect the fuel system periodically for signs of rust, sludge or microbial growth. Early detection can prevent significant problems.

Test Fuel

Routine fuel-quality testing helps identify issues before they escalate. Testing can detect contamination early, ensuring fuel meets the necessary quality standards.

Use High-Quality Fuel Additives

Fuel additives designed to manage water and prevent oxidation can enhance fuel stability and prevent fuel-system contamination.

• Cleans dirty injectors.

• Lubricates pumps and injectors to reduce wear.

• Protects fuel systems against water contamination.

• Combats fuel-system corrosion.

• Extends fuel-filter life.

• Improves fuel economy up to 8%.

• Restores power and torque.

• Reduces smoke and emissions.

• Helps prolong time between EGR and DPF regenerations.

• Reduces downtime and maintenance costs.

• Safe for use in all diesel fuels, including biodiesel.

The OAI Diesel Fuel Contamination Test Kit tests for water, sediments and aerobic bacteria. Includes 32-oz. container, UPS pre-paid shipping label, sample form and instructions.

Comments

Share: