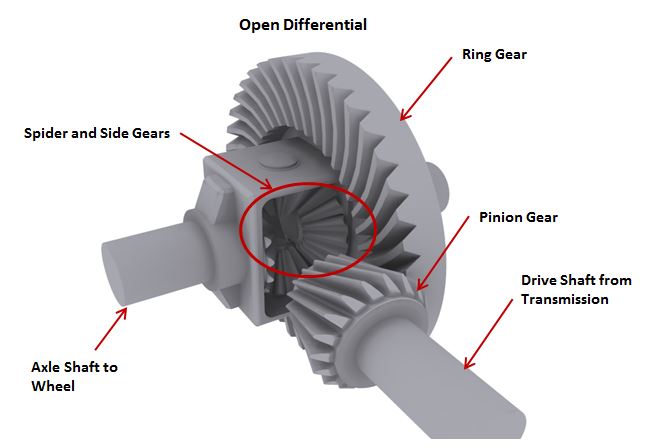

A differential is a set of gears that allows a vehicle’s driven wheels to revolve at different speeds when going around corners or over rough terrain. Those gears require lubrication, which is commonly called differential fluid, gear oil, or gear lube.

Modern vehicles produce substantially more horsepower, torque and towing capacity than their predecessors, yet the design of differential gears and bearings remains largely unchanged.

To reduce drag and increase fuel economy, many modern differentials also use less gear lube and lower viscosities. Therefore, less gear lube is responsible for providing more protection on a modern differential. Add towing into the mix and you’ll need heavy-duty lubrication.

Fighting the grind

Differential designs have inherent weaknesses. In a traditional automotive differential, the pinion gear concentrates intense pressure on the ring gear. As the gear teeth mesh, they slide against one another, separated only by a thin layer of lubricant.

“At 250,000 miles it is a big improvement, I should’ve made this change when I got my truck.”

– Javier T.

The repeated stress the lubricant film bears can shear gear lubes, causing permanent viscosity loss. Once sheared, the fluid film weakens, ruptures and allows metal-to-metal contact, eventually leading to gear and bearing failure. Severe-service applications, like towing, amplify the situation.

Thermal runaway

The extreme pressures and temperatures placed on gear lubricants can also lead to a serious issue called thermal runaway.

As temperatures in the differential climb, some gear lubes lose viscosity and load-carrying capacity. When extreme loads break the lubricant film, metal-to-metal contact occurs, increasing friction and heat. This increased friction and heat, in turn, results in further viscosity loss, which further increases friction and heat.

“I’ve used SEVERE GEAR in my race car for several years and the gears show no signs of wear.”

– Bruce M.

As heat continues to spiral upward, viscosity continues to spiral downward. Thermal runaway is a vicious cycle that leads to extreme wear and eventually catastrophic gear and bearing failure.

Severe-service operation requires more frequent differential fluid changes. Most vehicle manufacturers recommend changing differential fluid every 150,000 miles in normal service but dramatically reduce the change interval to every 30,000 miles when towing frequently at temps above 70ºF. That applies to anyone who pulls a camper, boat or trailer during warmer months.

“The front differential engages faster in my 4×4, but the Easy-Pack is worth it just for how easy it is to fill your differential.”

– Ryan N.

Keep it cool

AMSOIL SEVERE GEAR is designed to resist breakdown from extreme heat, helping prevent viscosity loss and acid, carbon and varnish formation. Its wax-free formula also improves cold-flow properties for better cold-weather performance.

SEVERE GEAR is also available in the award-winning AMSOIL Easy-Pack. Its flexible design makes performing tricky, hard to reach gear-lube changes easier, faster and cleaner. No more busted knuckles, annoying gear-lube pump and rigid bottles that waste half the fluid.

• Superior film strength to maintain viscosity

• Reduce temperature to control thermal runaway

• Protect against rust and corrosion

• Flexible Easy-Pack for fast, clean installation

Comments

AMSOIL Lead Technical Writer for more than two decades.

Share: