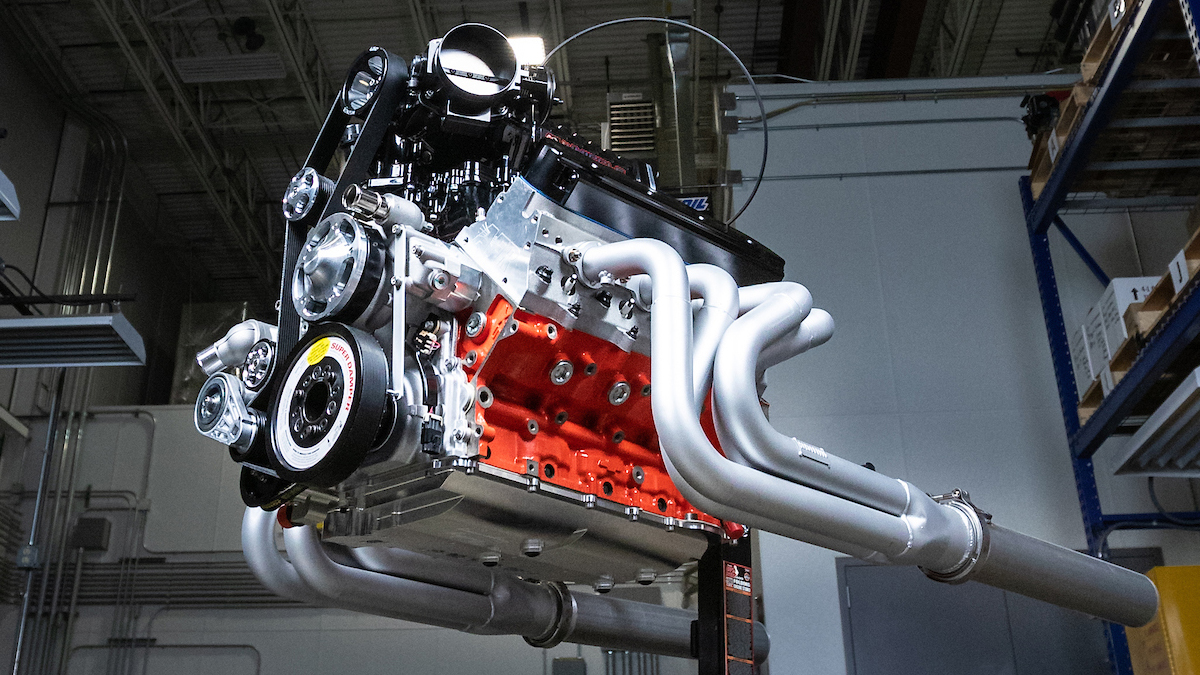

Used oil analysis is one of the most potent tools in your maintenance arsenal. It provides a simple, inexpensive and accurate glimpse inside your engine or equipment to help gauge lubricant and component condition, without removing a bolt or bloodying a knuckle. Here’s how to perform oil analysis.

What is oil analysis?

Oil analysis is the process of chemically analyzing a lubricant sample to determine the condition of the lubricant itself as well as the engine or other lubricated components it interacts with.

To have your oil analyzed, you must take a sample of the lubricant and ship it to a qualified laboratory. Technicians subject the lubricant to a range of tests to determine the concentration of wear metals, fuel dilution, the lubricant’s total base number (TBN), oxidation and other information. The lab will return a report on the lubricant’s condition and includes a brief explanation and recommendations for future service.

Benefits of oil analysis

Determining the condition of the oil inside your engine offers several benefits, all of which can save you time, money and hassle in the future.

- Maximize oil life

Monitoring the condition of the oil allows you to optimize drain intervals, so you can maximize the fluid’s service life. Performing fewer oil changes minimizes maintenance costs and reduces downtime for businesses that depend on equipment and vehicle availability. It also reduces the amount of waste oil, which helps the environment.

- Prevent equipment failure

Oil analysis identifies dirt, wear particles, fuel dilution, coolant and other contaminants that can cause catastrophic failure or significantly shorten equipment life, allowing you to proactively fix problems before they happen.

- Increase resale value

Oil analysis creates documentation of the equipment’s history and performance, which helps it maintain its value.

How to perform oil analysis

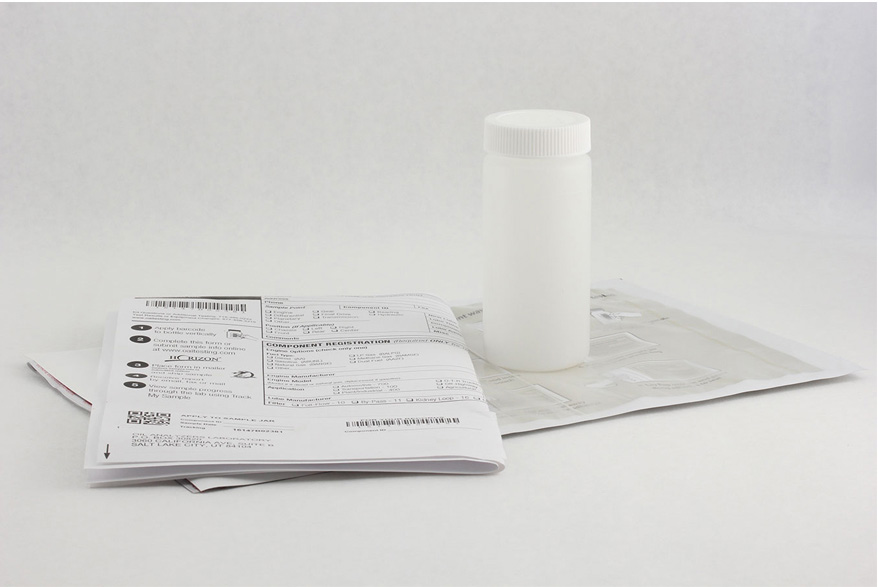

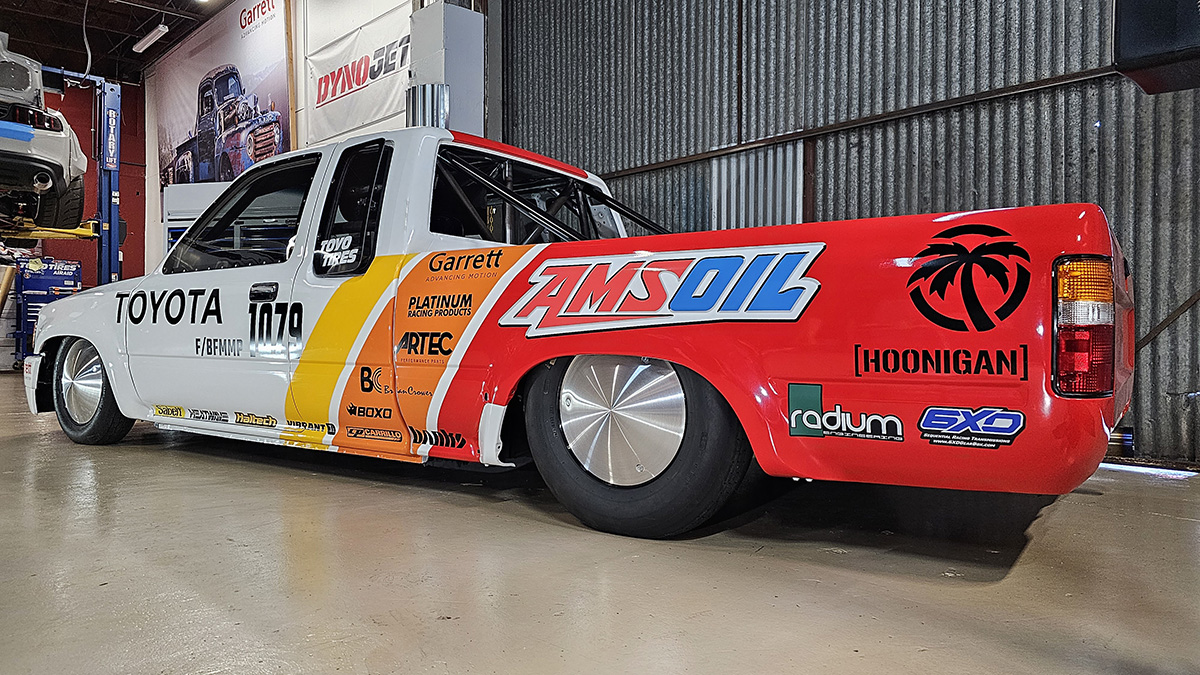

It is easy to perform oil analysis by obtaining an oil analysis kit from Oil Analyzers Inc. For this example, we used a 1998 Toyota* Corolla.* This vehicle was also used to demonstrate testing engine compression. Here’s what you’ll need to perform oil analysis:

- Oil analysis kit

- Sampling pump with hose

- Gloves

- Rag’

Warm up the engine

Warm oil flows more easily through the sampling pump and circulating the oil prior to drawing a sample ensures consistency. Run the vehicle for a couple of minutes; there’s no need to reach operating temperature.

Draw the oil sample

Using a vacuum pump is the easiest and cleanest way to accomplish this, allowing access to the oil sump through the dipstick tube. Thread the clean sample bottle included in the testing kit to the pump. Attach a clean hose (the length of the dipstick plus one foot) to the top of the pump and tighten the lock ring.

PRO TIP: Trim the end of the sampling hose at a 45-degree angle to make insertion easier.

Insert the hose into the dipstick tube until it bottoms out in the oil sump, then retract the tube about an inch, so it won’t pull contaminants off the bottom of the oil pan. Pump the plunger until the bottle is 3/4 full.

Sometimes it’s impossible to draw an oil sample from the top, so you’ll have to pull the sample straight from the drain hole, which is messier. Simply allow the lubricant to drain for a few seconds so contaminants that have settled around the drain plug are flushed out before catching a sample directly in the bottle. Quickly reinstall the drain plug and top-off the reservoir.

Ship the oil sample

Most oil analysis kits come with the appropriate labels and directions for shipping it to a lab. Follow the instructions, then sit tight until the results arrive.

Read the results

Oil Analyzers Inc. typically returns results either by email or via an online portal about two business days after receiving the sample. The lab report includes application information, elemental analysis and recommendations. The amount of information varies depending on the test kit you choose.

Comments

AMSOIL Technical Writer and 20-year veteran of the motorcycle industry. Enjoys tearing things apart to figure out how they work. If it can’t be repaired, it’s not worth owning.

Share: