As fun as it is to own a boat, they can create headaches if you neglect maintenance. Follow these boat maintenance and boat engine maintenance tips to help you avoid expensive repairs and stay on the water.

Boat Maintenance Checklist

Check Trailer Tire Pressure & Condition

Let’s start with a step that’s easy to overlook: boat trailer maintenance. You can’t get to the fish if you fail to get to the lake. It’s not uncommon to see someone pulled over alongside the highway because their trailer tire blew out.

Boat trailer tires typically run at higher psi than automotive tires. Check the sidewall for the correct pressure, which is likely around 50 psi.

A low tire equals a hot tire, and hot tires are more likely to blow out.

Check for weather cracking. Trailer tires often sit outside year-round, exposed to the sun. Replace cracked tires and store your boat and trailer with the tires elevated and covered during the off-season.

Grease Trailer Bearings

Like the tires, trailer bearings are easy to overlook. They are submerged in water every time you launch and load your boat.

Although the hub seals are designed to keep water out, age and neglect can allow water intrusion, which invites rust and corrosion.

Rust acts like sandpaper and scours the ball bearings, causing them to run hotter and boil the grease out, worsening the problem.

Grease the bearings as part of boat maintenance at least once a year with a high-quality synthetic grease designed to resist water washout, such as AMSOIL Synthetic Water-Resistant Grease.

Check out this video to see how to grease boat trailer bearings.

Change Lower-Unit Gear Lube

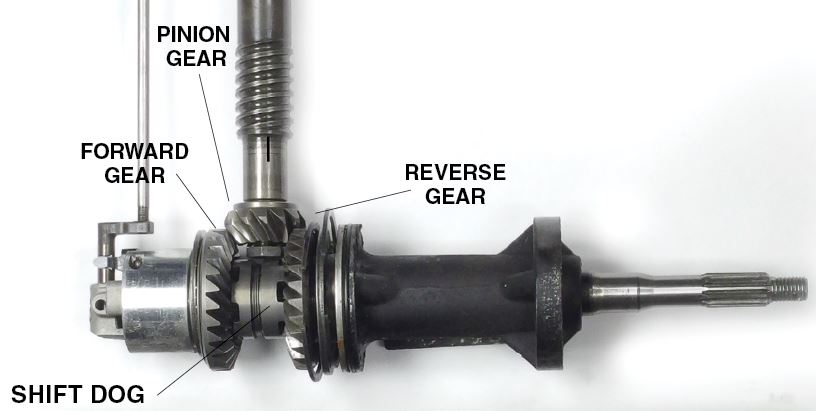

The lower unit houses gears, bearings and seals that require a quality gear lube to perform properly and last as designed.

The pinion gear concentrates extreme pressure on the ring gear teeth, especially during throttle bursts. If the lubricant film weakens (due to water intrusion, most likely) and fails to keep the gear teeth separated, they can chip and lead to failure.

This can also occur if you neglect to service the lower unit annually and allow the lubricant to deplete to a dangerously low level. The lubricant’s extreme-pressure properties are key to providing superior gear protection.

The shift dog is another area of concern.

It contains large teeth that mate with similar teeth on the forward or reverse gears, connecting the drive shaft to the prop.

If your outboard frequently pops out of gear, it’s likely due to rounded-over shift-dog teeth as a result of wear.

The shift dog is typically made of softer metal than the gears so it wears out instead of the gears, which are more expensive to replace.

Strong anti-wear properties are vital to ensuring the lower unit shifts properly and stays in gear.

Changing lower-unit gear oil can be a hassle when using rigid conical bottles or messy gear-lube pumps. The AMSOIL easy-pack makes the job much easier and cleaner. Check out the video to see it in action.

Check The Prop For Debris

While you’re changing the gear lube during your boat maintenance routine, remove the prop and check for wrapped fishing line or other debris. It can damage the seal that keeps water out of the lower unit, allowing water intrusion.

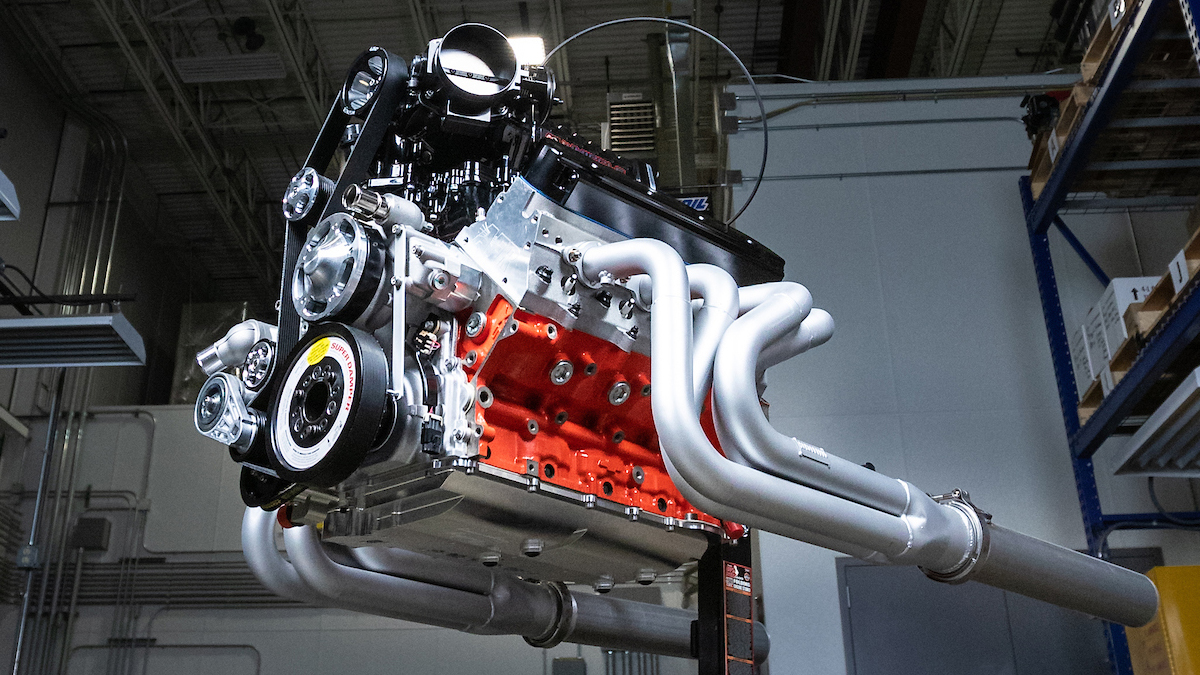

Boat Engine Maintenance: Change Oil & Filter

Engine oil is your lone defense against breakdowns and poor performance due to wear and deposits.

For best boat engine maintenance, change oil every fall prior to storage. That way you remove the acidic byproducts of combustion and ensure fresh oil is available to protect components against corrosion during storage. Don’t forget to change the oil filter, too.

Use an engine oil specifically designed for marine engines.

Contrary to popular belief, motor oil has no natural ability to prevent rust or corrosion. Instead, special rust and corrosion inhibitors must be added to the formulation to provide the required protection, and some oils simply don’t contain the correct additives in the correct concentration.

Rust and corrosion protection are vital given your engine’s exposure to water.

When you shut down the engine, some of the valves remain partially open, allowing damp air to infiltrate the combustion chamber. Rust and corrosion begin to form, creating contaminants that flake off and populate the oil, where it acts like sandpaper and scours metal surfaces until engine failure results.

To avoid this scenario, use an oil specifically formulated for marine engines, such as AMSOIL Synthetic Marine Engine Oil.

Treat Fuel Continuously During The Season

Most people are accustomed to using automotive fuel additives periodically. In marine applications, however, it’s best to use fuel additives with every tank of fuel.

Ethanol, present in most gasoline sold today, has a natural affinity for water. If moisture collects in your gas tank, it can bond with the ethanol and reduce performance.

Treat fuel with an additive designed to keep water dispersed in the fuel tank and prevent phase separation, such as AMSOIL Quickshot®. Continuous use also helps prevent formation of performance-robbing deposits, varnish and gums.

Grease Tilt Tube

Rust and corrosion can form on the tilt tube, preventing the motor from raising or lowering and restricting steering.

At the end of the season, grease the tilt tube using a water-resistant grease. In addition to protecting against rust and corrosion, seasonal greasing also eases steering input.

Drain & Clean The Livewell & Bilge

Transporting invasive species is a huge problem in some areas.

It’s a good idea to clean your bilge and livewell to prevent inadvertently introducing invasive species to an area river or lake.

When cleaning, avoid using caustic chemicals – they can harm the environment, not to mention your fish. Instead, buy biodegradable cleaners that are specifically recommended for cleaning the bilge or livewell.

Some boaters use warm water and baking soda. Simply let it soak for a while, scrub with a soft brush and rinse clean.

Cover Your Boat When Not In Use

The sun’s UV rays can turn your beautiful boat into trailer trash in just a few short years if you fail to protect it.

A covered boat lift is the best method. It’s effective without the hassle of unfurling and applying a cover every time you finish a day on the water.

Most enthusiasts can’t afford a covered lift or don’t have room for one. In this case, take the time to cover your boat when you’re done using it.

It may be frustrating to apply a cover, especially if it’s windy, but you’ll reap the benefits in the form of not having to reupholster your boat seats or replace carpet. Once the seat fabric dries out and cracks, it’s just a matter of time before the cushion deteriorates and the seat becomes useless.

Boat Maintenance: Wash & Wax

Another key entry on any boat maintenance checklist is to periodically wash and wax the hull on fiberglass boats. Otherwise, the coating can oxidize and deteriorate.

Also, neglecting to clean upholstery or canvass invites mildew, so clean everything periodically with chemicals designed specifically for marine applications.

Take these boat maintenance steps and your boat should deliver excellent service for years.