Motor oil tests

Here are some additional details on common tests required for motor oil certification.

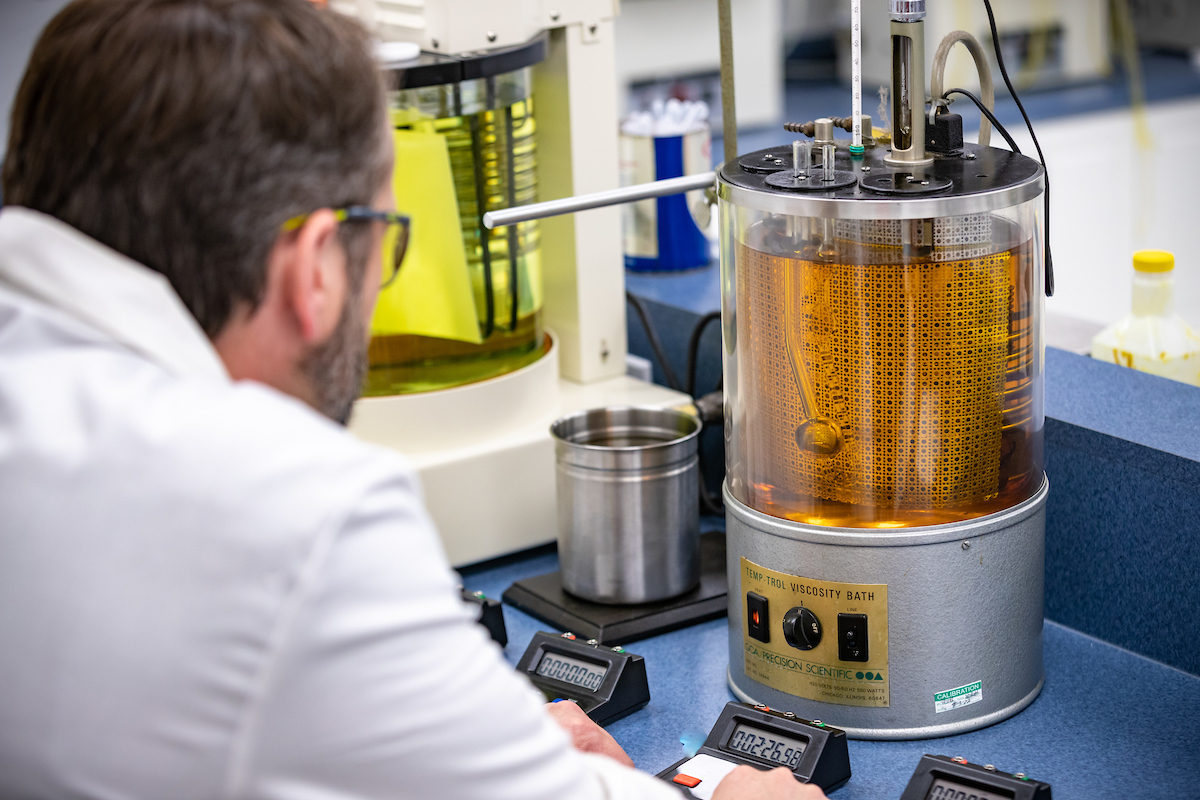

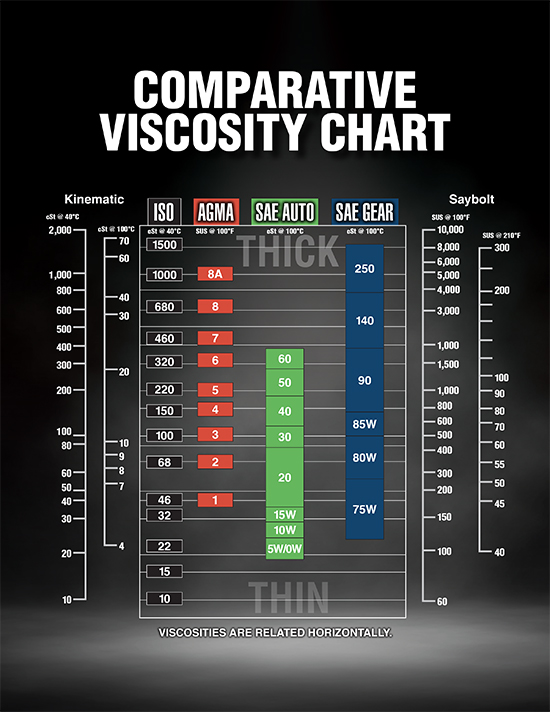

ASTM D2270 measures viscosity index or the variation in motor oil’s kinematic viscosity between ambient and operating temperatures (40˚C and 100˚C). A higher viscosity index indicates a smaller decrease in viscosity as temperature increases, meaning the oil maintains its structure better as temperatures increase. Additionally, ASTM D445 tests the actual viscosity at both 40˚C ambient and 100˚C operating temperatures.

Heated oil has an additional risk of shearing, or losing viscosity, under pressure. ASTM D5481 (HTHS) measures viscosity under temperatures and pressures representative of engine operating conditions. Applying stress to the oil via pressure provides insight into viscometric properties that other viscosity testing cannot, because engine oil additives introduce characteristics that can alter flow.

As much as we want oil to maintain viscosity in extreme heat, we also want it to remain fluid in extreme cold. ASTM D97 tests the pour point, which identifies the lowest temperature at which the lubricant will continue to flow. Additionally, ASTM D5293 (CCS) simulates the viscosity of engine oil in relation to cold engine cranking, which ensures the oil remains fluid enough to start an engine at a prescribed temperature.

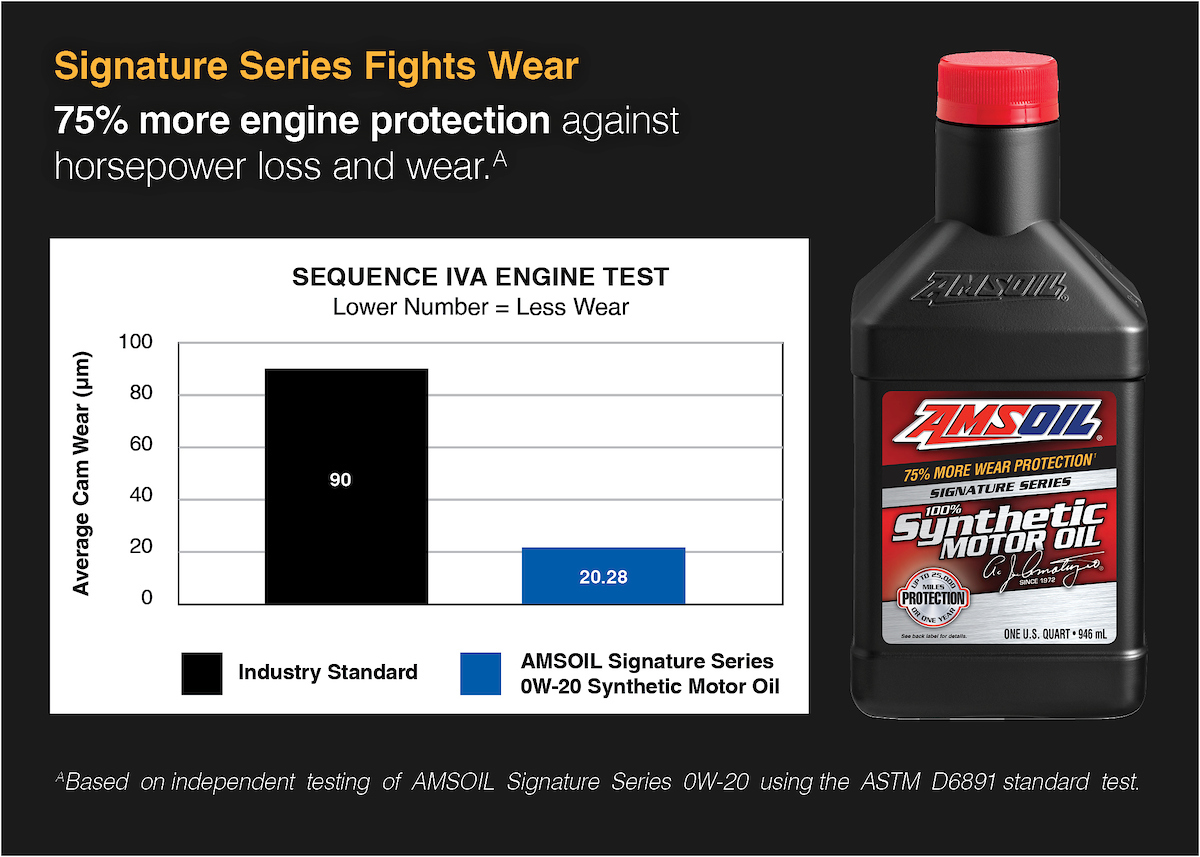

Because the primary purpose of oil is to reduce wear from metal-on-metal contact, ASTM D4172, aka the four-ball wear test, determines the relative wear-preventing properties of lubricating oils in sliding contact under prescribed test conditions. We also measure the oil’s ability to neutralize acids using ASTM D2896, which provides the Total Base Number (TBN). Lubricants with a higher TBN are more effective at suspending wear-causing contaminants and reducing the corrosive effects of acids over time.

Comments

AMSOIL Market Manager and product expert.

Share: