It is common knowledge that, at some point, motor oil must be changed. It’s something that is preached relentlessly to vehicle owners by vehicle manufacturers, quick lubes and oil companies. But what exactly makes oil changes necessary?

Many factors contribute to a motor oil’s demise, but it is essentially the accumulation of contaminants and chemical changes in the motor oil that make it unfit for further service.

With time, it is inevitable that the oil will be contaminated by dirt or sludge or succumb to the extreme pressures or temperatures found inside an engine.

AMSOIL synthetic motor oils are formulated with the industry’s most advanced synthetic base stocks and additive packages to combat the forces that deteriorate conventional oils.

Extreme Heat

Modern engines run hotter than ever. More horsepower, turbochargers and aerodynamic styling have created extremely hot environments that receive less cooling from outside air. High heat leads to oil oxidation, deposits and thickening, especially in conventional oils.

Because they are made from impure, irregular molecules, conventional motor oils are more susceptible to the effects of heat. The small, light molecules in conventional oil tend to evaporate as the oil is heated, leaving large, heavy molecules behind that lead to oil consumption and a viscosity increase. If those large, heavy molecules are chemically unstable, they may also break down and form deposits on component surfaces, further inhibiting the release of heat into the oil stream.

Even in relatively mild temperatures, oxygen works to break down some of the chemicals in conventional lubricants. The extreme heat in engines accelerates oxidation. When conventional oil contaminants break down, they coat components with varnish, deposits and sludge and render the lubricant thick, hard-to-pump and lacking heat transfer ability.

Extreme Cold

Cold temperatures cause oil to thicken. Conventional lubricants contain paraffins which cause them to thicken in cold temperatures as the paraffin gels. At startup, this can leave working parts unprotected for as long as five minutes while the oil warms to a temperature that allows it to flow.

Common Contaminants

Dust and dirt from the air enter the engine through faulty air cleaners, some oil-fill caps and crankcase ventilation systems. Normal engine wear produces small metal particles that are picked up and circulated by the oil.

The abrasive particles of road dust and dirt increase the rate of wear and generate larger metal particles. Those particles are equally abrasive and the rate of wear accelerates with a snowball effect.

While filtration removes most of these contaminants, some remain and are left to circulate with the oil.

Combustion By-Products

Combustion byproducts also act as contaminants. Water and acids produced during combustion lead to sludge, rust and corrosion. Soot and carbon create sludge and varnish and can clog filters. Unburned fuel in liquid form is deposited on cylinder walls where it leaks past the rings into the crankcase. Sludge deposits collect on oil pump screens, limiting the flow of oil to vital engine parts that leads to rapid and destructive wear. When oil becomes contaminated, its viscosity changes.

With soot, dirt, oxidation or sludge, viscosity increases, with fuel dilution it decreases.

Internal Forces

Engines create a great deal of internal pressure. Extreme pressure can result in boundary lubrication which breaks the oil film between moving parts. Movement inside the engine agitates the fluid, trapping air and forming bubbles or foam. Because air is compressible, the ability of the fluid film to prevent contact is reduced. And because the mixed air contains oxygen, it promotes oil oxidation.

Additives

Careful research and experimentation led lubricant manufacturers to specific chemicals that combat various problems faced by motor oils. These chemical additives are added to base oils as a package.

Typical additive packages can include rust and corrosion inhibitors, detergents, dispersants, antifoaming agents, oxidation inhibitors, extreme pressure additives and viscosity index improvers. Each additive is designed to aid the base oil in the protection of components, but additives have their limitations.

While these additives are created to perform specific tasks, they are also subjected to the same extreme environment experienced by the base oil, and each additive is affected by different variables in different ways.

For example, viscosity index improvers are used to reduce the thinning effects caused by operation at elevated temperatures. They are the key components that allow for the production of multigrade oils. However, the long molecules in viscosity index improvers are subject to shearing in service, which reduces their ability to minimize fluid viscosity loss. Permanent shearing of viscosity index improvers can result in piston ring sticking due to deposit formation, increased oil consumption and accelerated equipment wear.

High quality additives perform best and last longer when paired with high quality synthetic base oils.

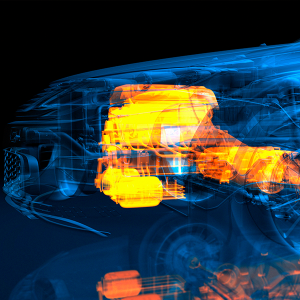

It’s All in the Molecules

Conventional lubricants are made from refined petroleum, a naturally occurring and impure substance. The varied and non-uniform size and shape of the molecules that make up conventional oils lend themselves to contamination. They cannot withstand extreme heat or cold, and they burn off and succumb to oxidation, leading to the development of deposits and component wear.

AMSOIL Synthetic Motor Oils

AMSOIL synthetic motor oils provide extended equipment life, reduced maintenance costs, better performance, improved fuel economy and extended drain intervals through the use of high-quality synthetic base stocks and superior additive packages.

Because they are derived from pure chemicals, synthetic lubricants contain no unnecessary molecules. Their smooth lubricating molecules slip easily across one another, improving the lube’s ability to reduce friction, which in turn improves wear control, heat control and fuel efficiency.

In addition, uniformly sized synthetic lubricant molecules resist thinning in heat and thickening in cold, decreasing the need for viscosity index improvers and increasing the lube’s ability to maintain its viscosity.

Because AMSOIL synthetic lubricants contain only strong, uniform molecules, they are much more resistant to thermal and oxidative breakdown.

AMSOIL synthetics are virtually impervious to breakdown at normal operating temperatures and can be used in higher temperatures than conventional oils without breaking down. AMSOIL synthetic motor oils keep components free of varnish, deposits and sludge.

Extended Drain Intervals

AMSOIL synthetic motor oils do more than provide protection that’s superior to conventional oils; they also remain fit for service longer than conventional oils.

Heat and oxidation are the main enemies of lubricant base stocks. The excellent resistance of synthetic lubricants to thermal and oxidative breakdown allows them to be safely used for longer drain intervals than conventional lubricants.

For example, AMSOIL Signature Series 100% Synthetic Motor Oil is recommended for ultimate protection and 25,000-mile/one-year drain intervals.

The Choice is Clear

When AMSOIL synthetic motor oil was introduced in 1972 it was ahead of its time. Today, engine designers have goals of increased fuel economy, reduced exhaust emissions, more performance out of smaller engines and greater durability, increasing the demands placed on motor oils and requiring continuous upgrades. AMSOIL continues to lead the industry by providing motor oils that help extend the boundaries of vehicle performance.

Comments

Brad Nelson is a staff writer for AMSOIL. Outside of work he enjoys family adventures, wilderness exploration and riding/wrenching on vintage metric motorcycles.

Share: