Modern engines have undergone design changes meant to improve engine performance, increase fuel economy and help reduce emissions. Some of these design changes include direct injection systems (DI), turbochargers and advanced after-treatment systems such as exhaust gas recirculation (EGR) and diesel particulate filters (DPF).

These design changes have made the operating environment inside the engine more severe, and engine oil formulations have also had to evolve to perform in these harsher conditions. The new emissions systems place further stress on oil, requiring the new formulations to remain compatible with advanced emissions components. New heavy-duty diesel trucks generate higher operating temperatures and increased levels of soot and acid, creating additional challenges for diesel oils.

Engine Oil Formulation

Many of the components inside internal combustion engines (ICE) rely on engine oil for protection in order to reach or exceed the engine’s expected operating life. Engine operating environments vary according to the engine’s design, so two-stroke, four-stroke, air-cooled, water-cooled, diesel, gasoline and natural gas engines all have different operating characteristics due to their design and fuel source.

While many motorists traditionally believed engine performance relies on frequent (3,000-mile) oil changes, the truth is that engine oil does not automatically go bad once it’s accumulated a certain number of miles. Rather, engine oil quality and its ability to protect and lubricate the engine depends on several performance properties engineered by the oil manufacturer. The performance life of the oil is also heavily impacted by environmental factors and the application in which it is used.

To properly protect the engine, lubrication oils are formulated with a combination of base oils and additives based on each specific application. The performance properties of motor oil can range from general to specialized. The basic functions of an engine oil include:

- Reduce friction and wear

- Cool engine components

- Minimize combustion byproduct contamination

- Seal components to prevent leakage

- Protect against rust and corrosion

- Dampen shock from extreme pressure

- Enhance fuel economy

- Emissions system compatibility

- Improve equipment life expectancy

Base Oil

An engine oil’s formulation begins with a base oil that provides several key performance properties the engine requires and provides most of the finished oil’s oxidation, soot-handling, viscometrics, volatility, dispersancy and solvency performance properties. Higher quality synthetic base oils provide better oxidative stability, are more resistant to chemical and mechanical breakdown, help prevent contaminants from settling in the engine and resist evaporation.

Additives

Additives are used to combat destructive processes and enhance beneficial properties of the base oil. Building an additive package is a balancing act because some additives counteract the effects of other additives. The focus of additives is enhancing the performance characteristics most beneficial for the intended application. Additive packages may include:

- Antioxidants

- Solvents

- Anti-wear additives

- Extreme-pressure additives

- Rust and corrosion inhibitors

- Seal conditioners

- Friction modifiers

- Anti-foam additives

- Detergents

- Dispersants

- Sulphated ash

- Phosphorus

- Sulfer

Operating Conditions

The performance abilities of engine oil depend highly on how it is used. The following operating conditions influence engine oil performance and formulation:

- Temperature

- Environmental

- Load

- Speed

- Engine design

- Fuel type

- Fuel-delivery system

- Service Duty

- Cooling system

- Emissions system

Standards and Specifications

Industry organizations and vehicle manufacturers establish performance requirements that lubricants must meet to be used safely in specific equipment. When you pick up a quart of oil and the label states that it meets the “API SP” specification, you know the oil will provide reliable performance and protection and is safe to use in your vehicle that requires API SP oil. Standards and specifications function as safeguards that protect motorists from the negative effects of low-quality lubricants and take the guesswork out of selecting the correct lubricant.

Some common elements involved in defining lubricant specifications include:

- Scope of application

- Physical and chemical properties

- Performance properties

- Product compatibility

- Testing methods

- Approval process

U.S. Performance Standards

Over time, technologies and materials change, requiring engine oil technology to also change to remain compatible and achieve certain performance requirements. Additionally, federal and local legislation may enforce certain performance standards, such as reduced emissions, which are affected by engine oil. For example, Congress has mandated corporate average fuel economy (CAFE) standards since 1975 with each new iteration requiring improved fleet-wide fuel economy. Engine oil can be engineered to improve fuel economy and help vehicles meet those requirements.

The creation and management of engine oil performance standards in the U.S. is conducted by the American Petroleum Institute (API) and the International Lubricant Standardization and Approval Committee (ILSAC). The API and ILSAC establish minimum performance requirements for gasoline and diesel engines. Consumers can use these service categories to select oils that are compatible with their vehicle technology and ensure maximum fuel economy.

It has also become common for vehicle manufacturers to introduce their own proprietary motor oil specifications, such as Volkswagen* VW* 502.00/505.00, BMW* BMW LL-04 or General Motors* dexos.* These manufacturer specifications tend to be more stringent than industry specs.

API Service Categories

The API service categories are divided into separate classifications for gasoline and diesel engines. Gasoline engine oils fall under the Service (S) category, while diesel engine oils fall under the Commercial (C) category. Each category represents a minimum level of engine oil performance, which can be demonstrated by laboratory and engine testing.

Most vehicle manufacturers have traditionally recommended a specific API service category oil to be used in their engines to provide adequate protection and performance. New service categories are developed as needed due to changes to federal legislation, manufacturing materials and fuel economy improvements. Gasoline engine oils can be engineered to satisfy more than one service category, and new service categories generally include the performance properties of earlier categories. For example, if a vehicle calls for API SN oil, a newer API SP oil will also provide the necessary protection.

Diesel oils will usually include the performance properties of earlier categories, but not always; therefore, it is always important to check the manufacturer oil recommendations to ensure the right oil is chosen. API service category oils focus on the following performance characteristics:

- Engine cleanliness – detergency, dispersancy and soot handling

- Durability – oxidative stability, inhibiting acid (TBN) and rust and corrosion protection

- Fuel economy – lubricity

- Wear protection – viscosity, film strength and anti-wear additives

- Emissions-system compatibility

API Four-Stroke Gasoline Engine Standard:

API SP service category was introduced in 2020 and is appropriate for all gasoline passenger cars and light trucks.

• Protects against low-speed pre-ignition (LSPI) and timing chain wear

• Increased high-temperature protection for pistons and turbochargers

• Increased sludge and varnish control

• Improved fuel economy, emissions system compatibility and seal compatibility

• Protects engines running on ethanol fuels (up to E85)

• Increased oxidation resistance, low-temperature performance and wear protection

• Compatible with engines requiring the previous SN, SM, SL, SJ standards

API Four-Stroke Diesel Engine Standards:

FA-4 is designed for model year 2017 and newer diesel engines.

• Not for use in MY 2016 and older vehicles, or where API CK-4 or earlier are specified

• Improved wear protection, thermal stability and viscosity and aeration control

• Maintains emission-control systems with particulate filters and other after-treatment systems

CK-4 is designed for all current diesel engines and is backward compatible.

• Improved wear protection, thermal stability and viscosity and aeration control

• Meets exhaust emissions standards and compatible with EGR exhaust systems

• Improved protection in hostile environments

• Reduced sulfated ash (metal byproducts of combustion)

• Compatible with high- and low-sulfur fuel (ULSD)

• Improved soot-handling abilities and shear stability

• Compatible with engines requiring the previous CJ-4, CJ-4+, CI-4, CH-4 standards

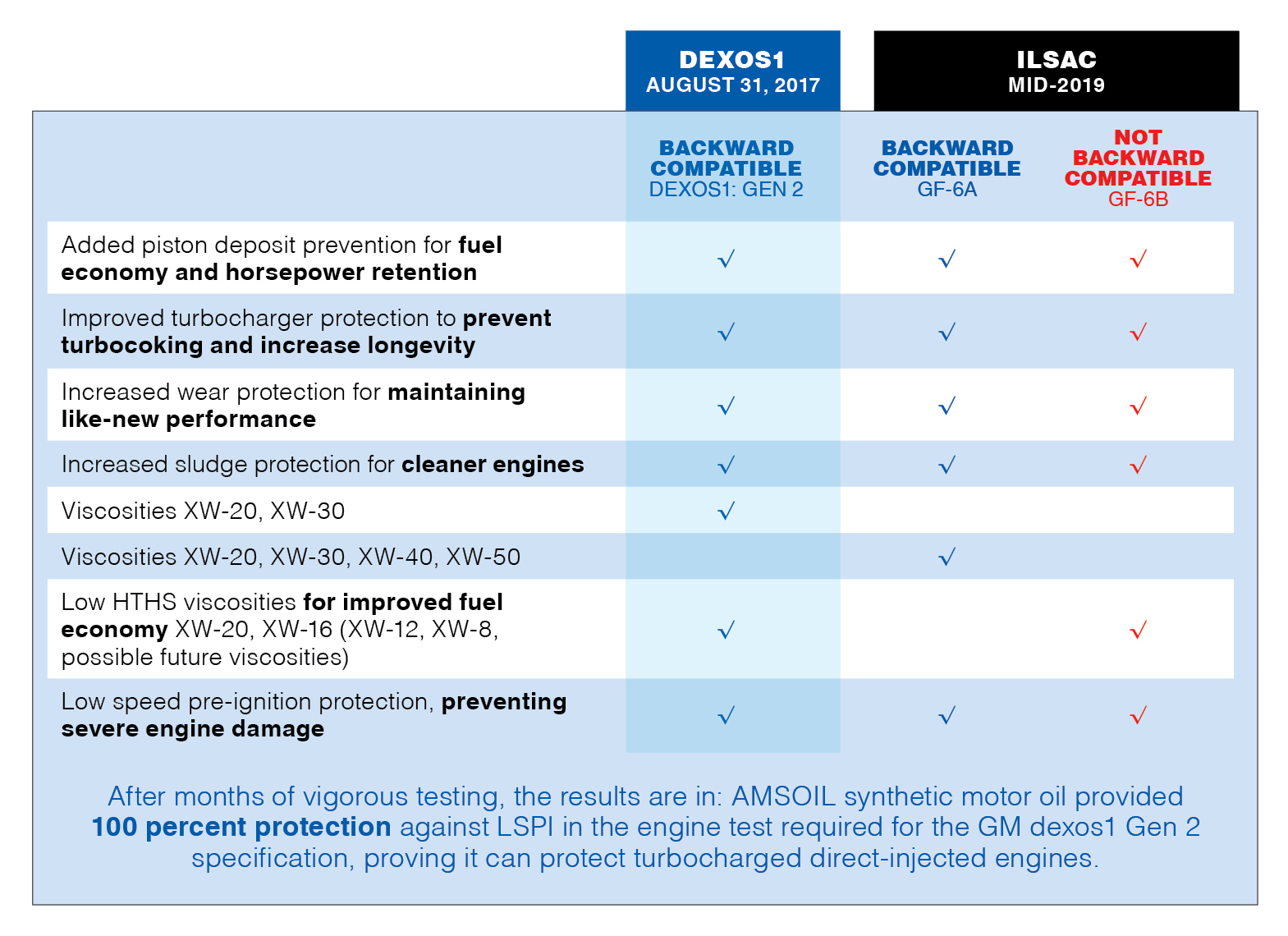

ILSAC Specifications

The ILSAC engine oil standards are developed for gasoline engines and focus on fuel economy retention, engine oil robustness and emissions-system protection.

ILSAC Four-Stroke Gasoline Engine Standard

GF-6A Introduced in May 2020 to provide

• protection against low-speed pre-ignition (LSPI) and timing chain wear.

• Increased high-temperature protection for pistons and turbochargers

• Increased sludge and varnish control

• Improved fuel economy, emissions system compatibility and seal compatibility

• Protection for engines running on ethanol fuels (up to E85)

• Replaces obsolete GF-5, GF-4, GF-3, GF-2, GF-1 standards

GF-6B Applies only to SAE viscosity grade 0W-16 and not backward compatible.

• protection against low-speed pre-ignition (LSPI) and timing chain wear.

• Increased high-temperature protection for pistons and turbochargers

• Increased sludge and varnish control

• Improved fuel economy, emissions system compatibility and seal compatibility

• Protection for engines running on ethanol fuels (up to E85)

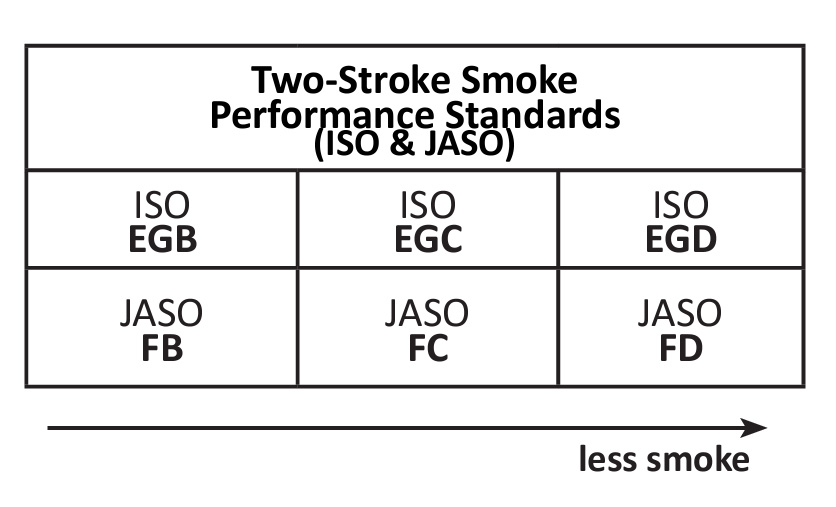

NMMA Specifications

The National Marine Manufacturers Association (NMMA) is a trade organization that represents boat and marine engine and accessory manufacturers. The NMMA manages the FC-W standard for four-stroke outboard and TC-W3 standard for two-stroke outboard engines. The standards are designed to reduce emissions and increase engine life and consumer satisfaction with outboard engine oils. The TC-W3 standard is a performance-based program with rigorous testing for properties such as fluidity, lubricity, rust prevention, smoke production, detergency and ring sticking.

Comments

AMSOIL Technical Writer and 20-year veteran of the motorcycle industry. Enjoys tearing things apart to figure out how they work. If it can’t be repaired, it’s not worth owning.

Share: